- Home

- >

- Products

- >

- Duct Heater

- >

Duct Heater

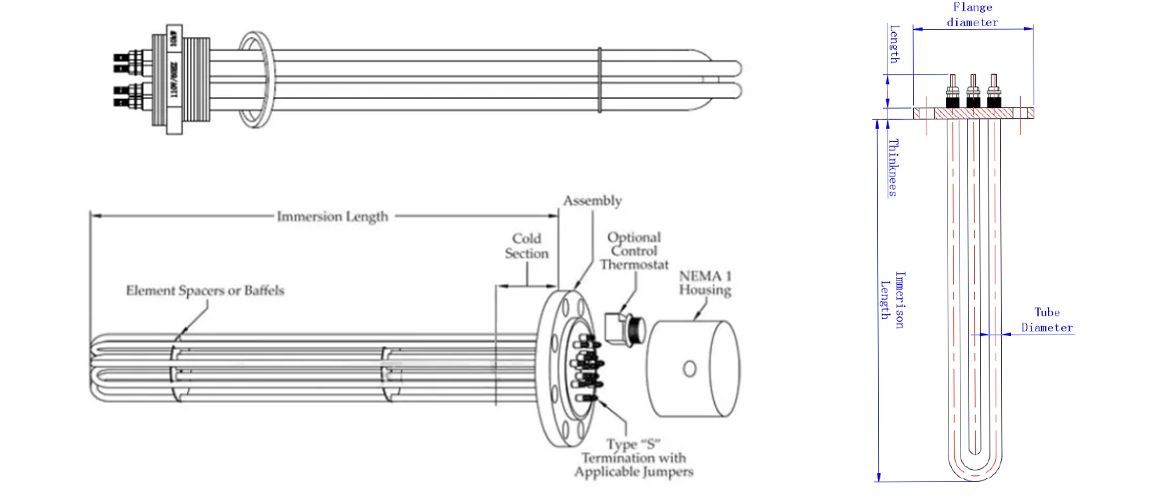

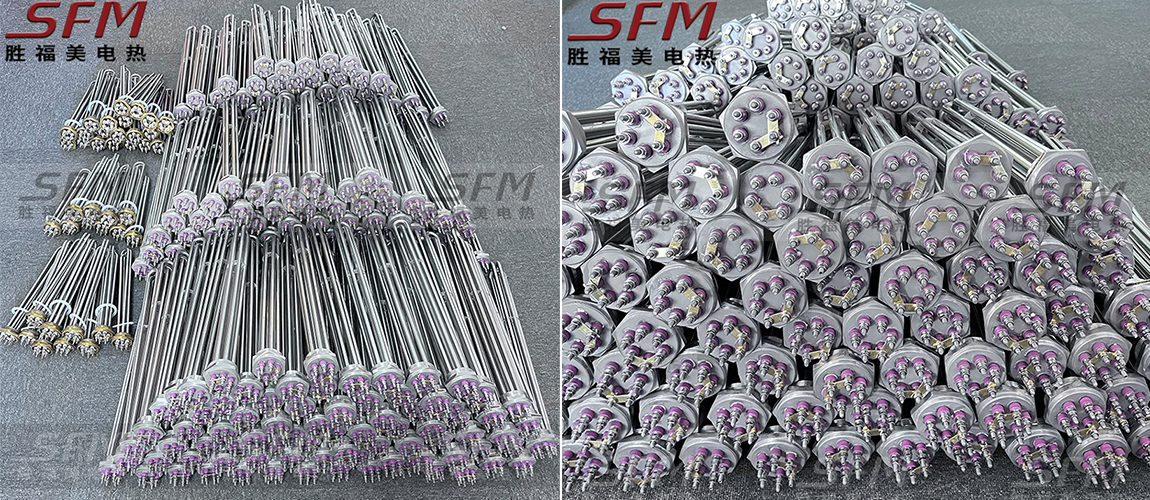

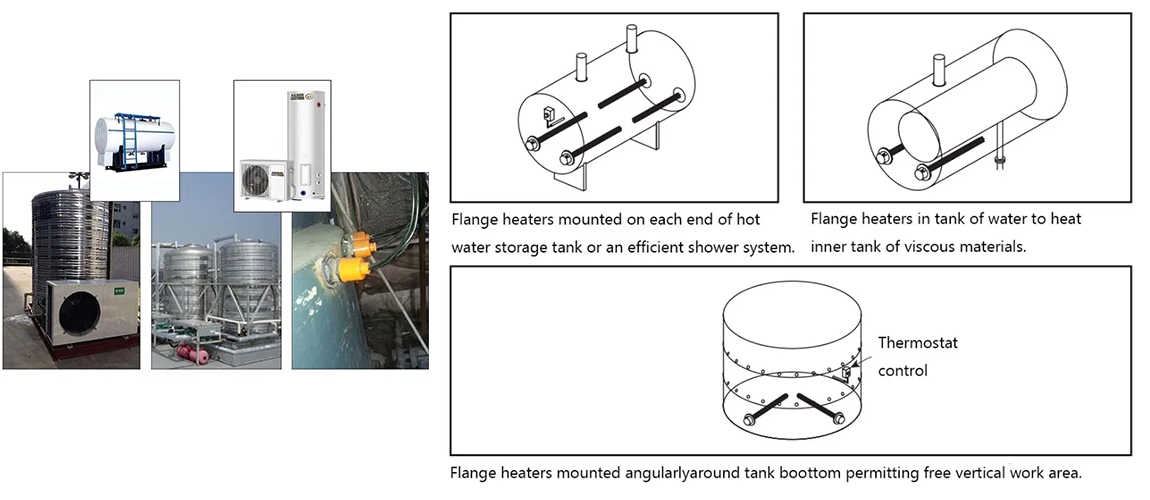

Flanged immersion heaters consist of hairpin bent tubular elements welded or brazed into a flange and provided with wiring boxes for electrical connections. Flange heaters are installed by bolting to a matching flange welded to the tank wall or nozzle. A wide selection of flange sizes, kilowatt ratings,voltages, terminal housings and sheath materials makes these heaters ideal for all types of heating applications

- SFM

- China

- 7-9 day

- Information

Flange size | DN 40 to DN 800 |

Screw plug size | 1"- 3" |

Immersion Length | 150mm- 1500mm |

Heating Element | 3 elements, 4 elements, 6 elements, 10 elements etc (under customer request) |

Wattage density | 2-8W/cm2 |

Voltage | UP to 600V |

Sheath Material | Stainless Steel 304 316L 310S Copper Incoloy 800 840 |

Built in thermostat well | Built-in thermostat wells can be installed upon request. When ordering, please provide length BUILT-IN THERMOSTAT WELL and internal diameter |

Wattage Tolerance | +5%, -10% |

Resistance tolerance | +10%, -5% |

Insulation resistance (cold) | ≥ 500 MΩ |

Maximum leakage current (cold) | ≤ 0.5 mA |

Dielectric strength | 1500 V |

Tube diameter | Φ2mm-Φ30mm |

Tube Material | Fe, SS304;SS316,SS321,ss202 etc |

Insulation Material | High-purity Mgo |

Reisistance wire element | Ni-Cr or FeCr |

Lead Connection Option | Crimped or Swaged leads |

Lead and type of connection leads | 10" Fiberglass Standard(Wire options,silicone high temperature frberglass) |

Voltage and power | customized |

Shape | customized according to drawing |

Warranty | one year |

2: How to choose the power size

The power calculation formula is: required power (kw) = weight of water (kg) x temperature difference x specific heat capacity of liquid {kJ/(kg C)}/time (seconds)

Example: What is the power of the electric heating tube required to heat 1000kg of water to 50°C with an initial temperature of 10°C in 1 hour (3600s)? The specific heat of water is 4.2, which can be substituted into the formula to obtain 46.66KW. There is heat dissipation during the actual heating process, and the required wattage needs to be larger than the theoretical calculation value.

3: How thick the wire is to choose

The higher the wattage, the faster the heating speed, but it still needs to be able to withstand the line and the circuit breaker. The thickness of the wire and the open circuit can be selected according to the current in the line

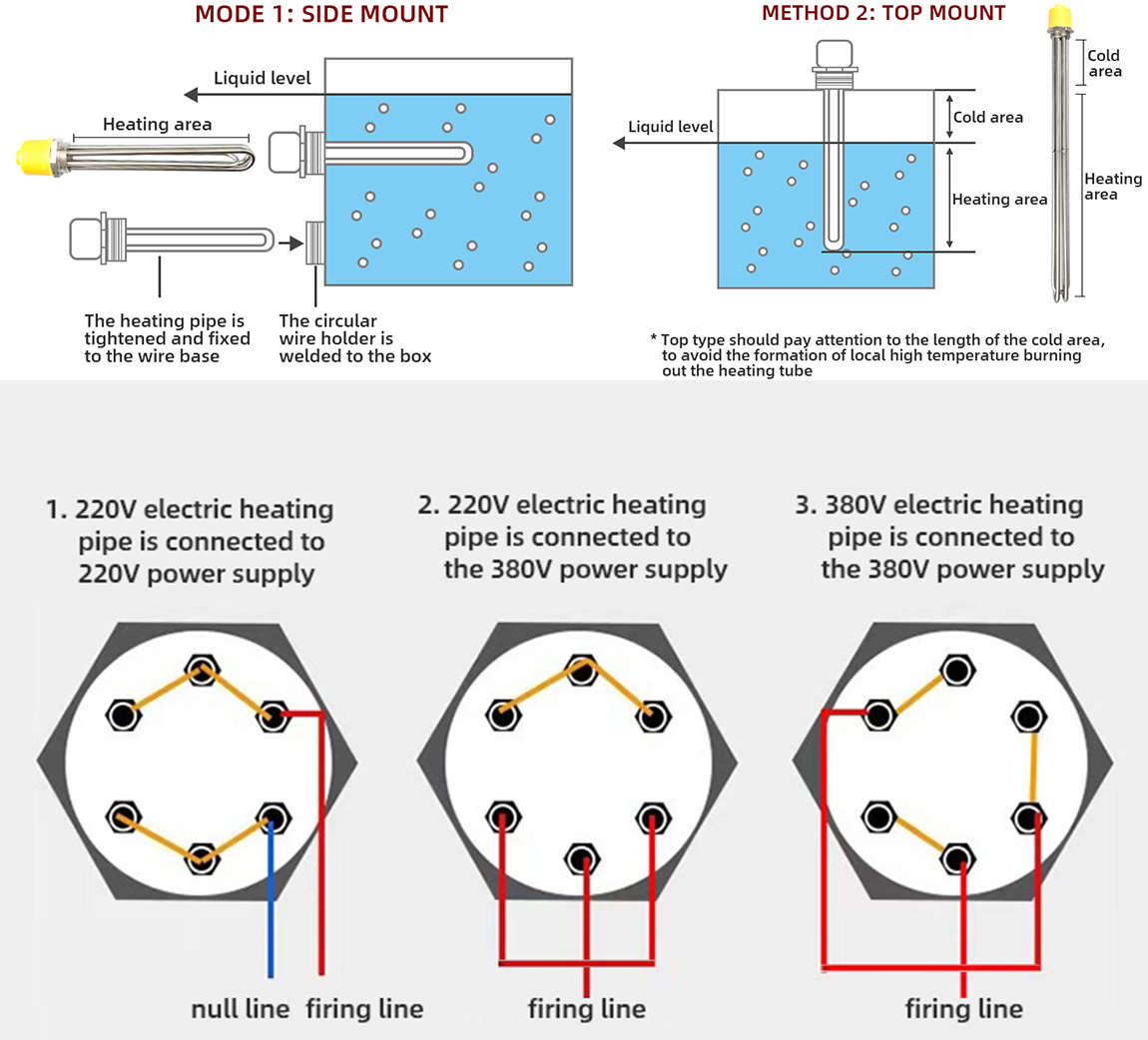

1: The current of a single 220V electric heating tube: connect 1 zero to 1 fire, line current = power ÷ 220

2: A single 220V electric heating tube is connected to three-phase power by Y connection:

Connect 3 fire wires, line current = power ÷ 380-1732

3: Single 380V electric heating tube △ connection to three-phase electricity:

Connect 3 live wires, line current = power ÷ 380 ÷ 1732

1 zero 1 fire connected to single-phase electricity | The Y connection method is included in the three-phase electricity | △The connection method is included in the three-phase electricity | |

220V 6KW | Line current = 27.2A | Line current = 9.1A | - - - |

220V 9KW | Line current = 40.9A | Line current = 13.6A | - - - |

380V 6KW | - - - | - - - | Line current = 9.1A |

380V 9KW | - - - | - - - | Line current = 13.6A |

380V 12KW | - - - | - - - | Line current = 18.2A |

4: Leakage, installation and use precautions

The new heating tubes are tested and delivered without leakage. As the heating tube is damaged during use, it will leak electricity. Therefore, the equipment shell must be reliably grounded and a leakage protection switch must be installed.

The replacement and installation of the heating element needs to be operated by a professional master to avoid safety hazards caused by improper operation.

total accident. Although the heating tubes have been tested before leaving the factory, it is recommended to use the

Use a meter to measure whether it is energized, use an insulation shaker to measure whether it is leaking, if it is in good condition, then

Install. In this way, if there is a problem after installation, the cause of the heating rod can be ruled out, and then the cause can be found from other aspects.

5:Is there electricity in the water? Consequences of improper use

When the heating rod is intact, there is a slight current in the water, which does not exceed the safe value. However, when the heating pipe is always broken, and the user's leakage protection device also fails, it is unsafe if it is broken at the same time. It is recommended that the human body should not touch water when the heating is powered on.

When the heating rod is energized, it must be completely submerged under water. If the heating rod is exposed to the water and burns dry, the tube may burst. Burning out the heating tube is a trivial matter, and it may also cause line safety problems.

6: common fault suggestion troubleshooting

· No fever? Slow fever?

A multimeter can be used to measure whether the resistance value of the electric heating tube is normal. If the resistance value is infinite, then

The heating tube has been blown. Use a clamp ammeter to measure the line current to see if the line current is equal and how much it deviates from the rated value.

Leakage? Trip?

You can first check whether the body of the electric heating tube has abnormalities such as burning black and cracking. If the shell is cracked, it is the leakage caused by the electric heating tube. If there is no abnormality on the surface, it can be tested again with an insulating shaker

Whether the electric heating tube is leaking. If the electric heating tube problem is ruled out or the electric heating tube is replaced

Tripping, it is recommended to check the aging of the circuit breaker one by one, the contact of the AC contactor is damp, and so on.