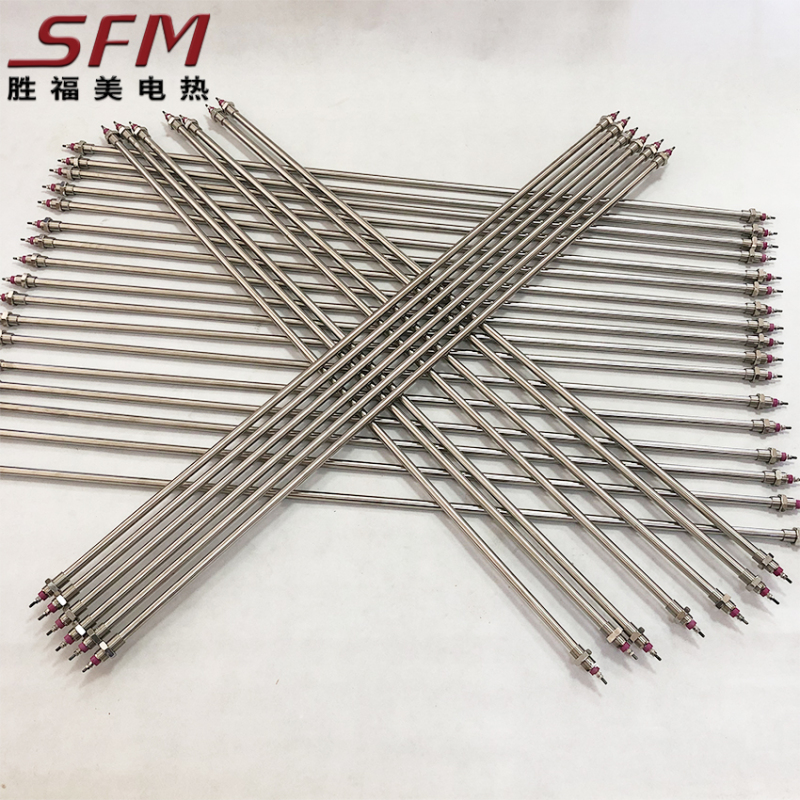

Straight Tubular Heater

The tubular heater’s basic construction consists of a computer-designed helical coil of 80% Nickel 20% Chromium alloy resistance wire fusion welded to the nickel-coated steel terminal cold pins. This assembly is precisely stretched and centered in the element metal sheath, which is then filled with Grade "A" Magnesium Oxide powder (MgO). The filled tube is then compacted by a roll reduction mill into a solid mass, permanently stabilizing the coil in the center of the tube while providing excellent heat transfer and dielectric strength between the coil and the sheath.

- SFM

- china

- 7-8 day

- Information

How to Choose The right Material for the tubular heaters? Please check this table. | |

Material | Maximum Sheath Temperature |

Copper | 350℉(170℃) Application: Water, Oil, Grease |

Steel | 750℉(400℃) Application: Alkaline cleaning solutions, Tars, Asphalt or air heating |

Stainless Steel | 1200℉(600℃) Application: Corrosive liquids, food processing equipment, Radiant heating |

Incoloy | 1500℉(815℃) Application: Cleaning and degreasing solutions, Corrosive liquids |

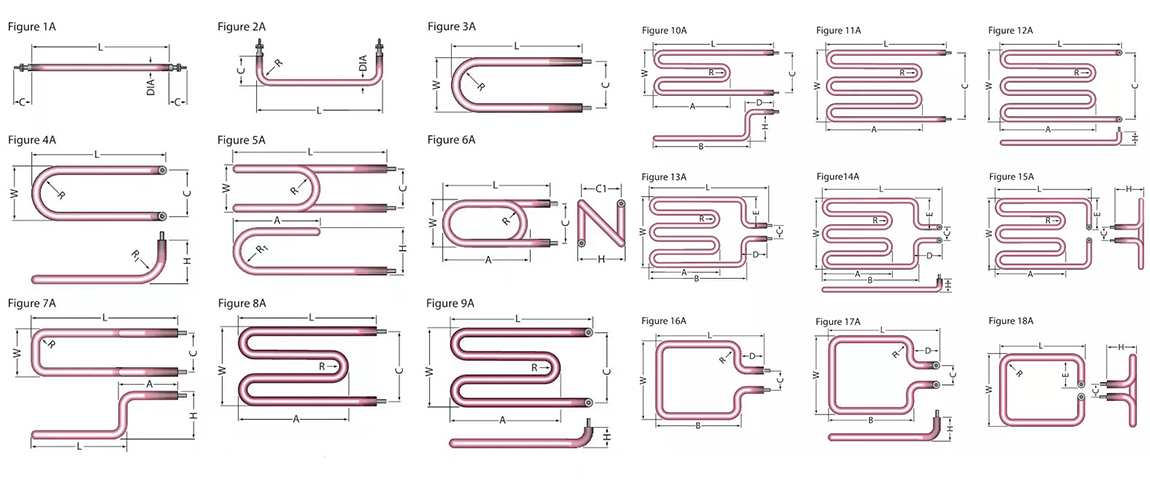

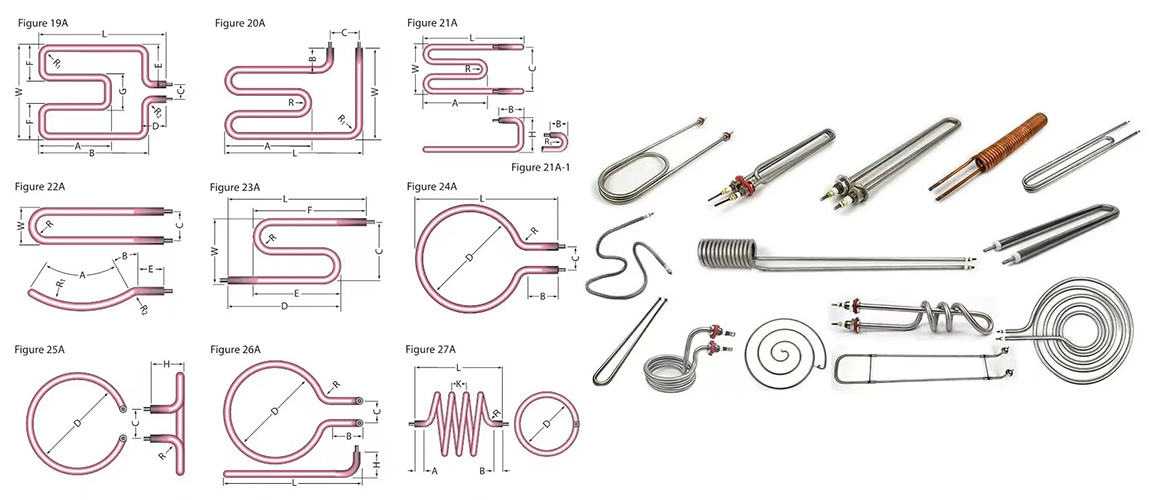

Stainless steel tubular heater is cylindrical electrical heating elements with two head. Protected with a stainless steel sheath. Mostly double head heater is used for heating up solids such as injection presses heating plates or various tools, double head heater can also be used for heating up water of gases under certain conditions.The choice of technology will depend on technical specifications required and the application.When you don't know exactly which product you are looking for, we will recommend you the best solution for your needs.Tubular heaters are custom designed in a various shapes to as client’s requirements for direct immersion in liquids such as water, oils, solvents and process solutions, molten materials as well as air and gases.

Tubular heaters are produced using Incoloy, stainless steel or Copper sheath materials and also there is huge variety of selection of termination styles available. Insulation of Magnesium offers greater heat transfer. Tubular heaters can be used in any application. Straight tubular can be inserted in machined groves for conductive heat transfer and formed Tubular provides consistent heat in any type of special application. Its applications areas are: Plastic processing machineries ;Engineering Industry ;Packaging machinery ;Shoe making machineries ;Foundry Equipment ;Radiant Surface heating ;Hot Runner Mould Systems etc

1.Voltage: 12-380v (customized), power: customized The power voltage needs to be confirmed. The wrong power voltage will cause slow heating or burn out the heating tube. It can be identified by the resistance value measured by the multimeter.

2. Thread specification: common M12, M14, M16, M18. (customized) The mounting holes of the big and small medicine boxes of the screw head are matched, otherwise, the water will leak or the installation will not go in. It can be measured with caliper or spanner wrench.

3. The center distance of the terminal (corresponding to the hole distance of the installation hole) is customized. It's the same as the old heating pipe.