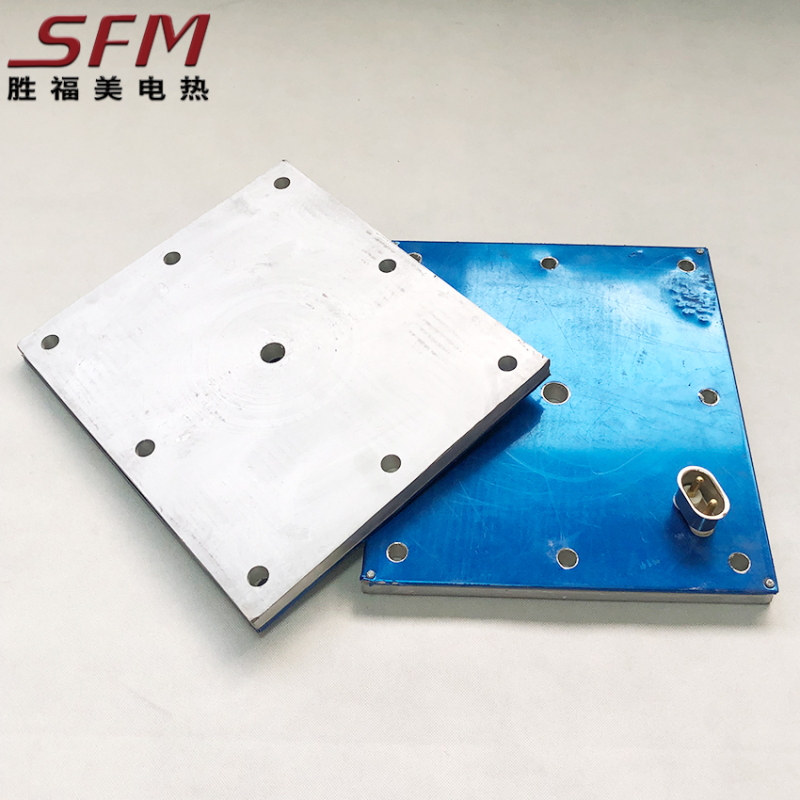

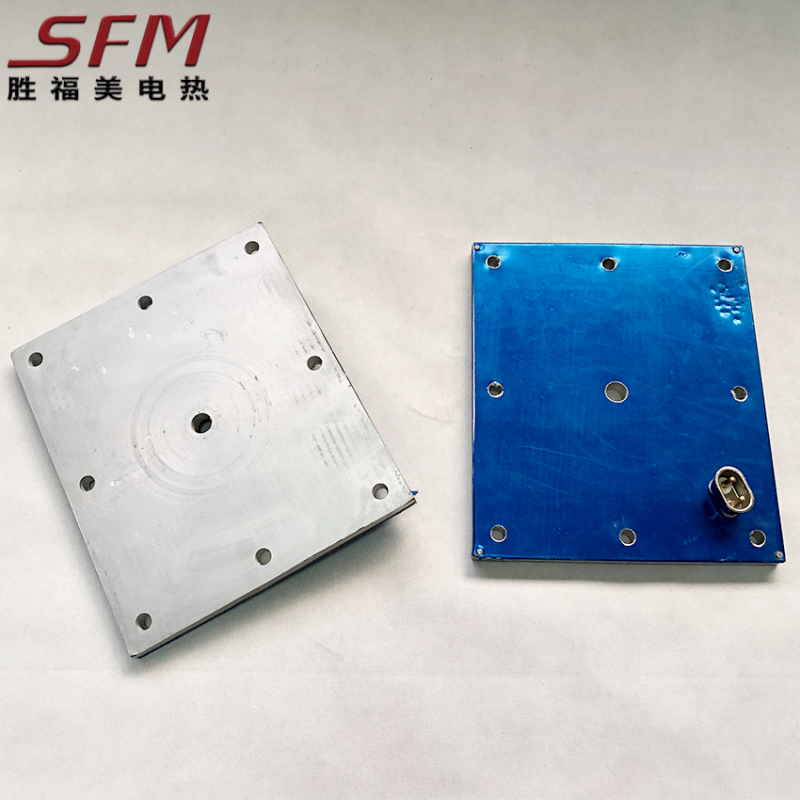

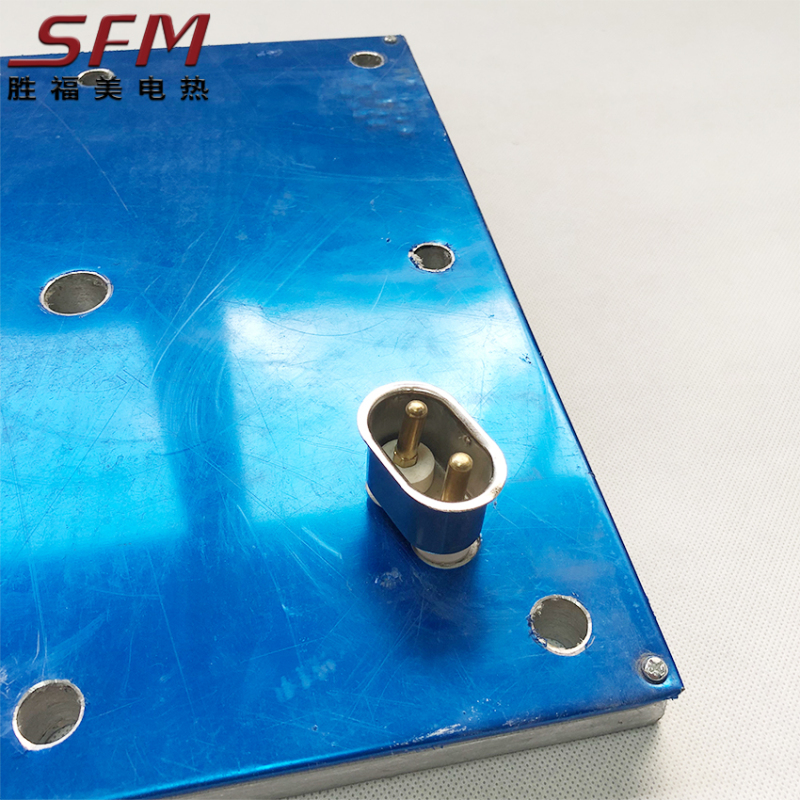

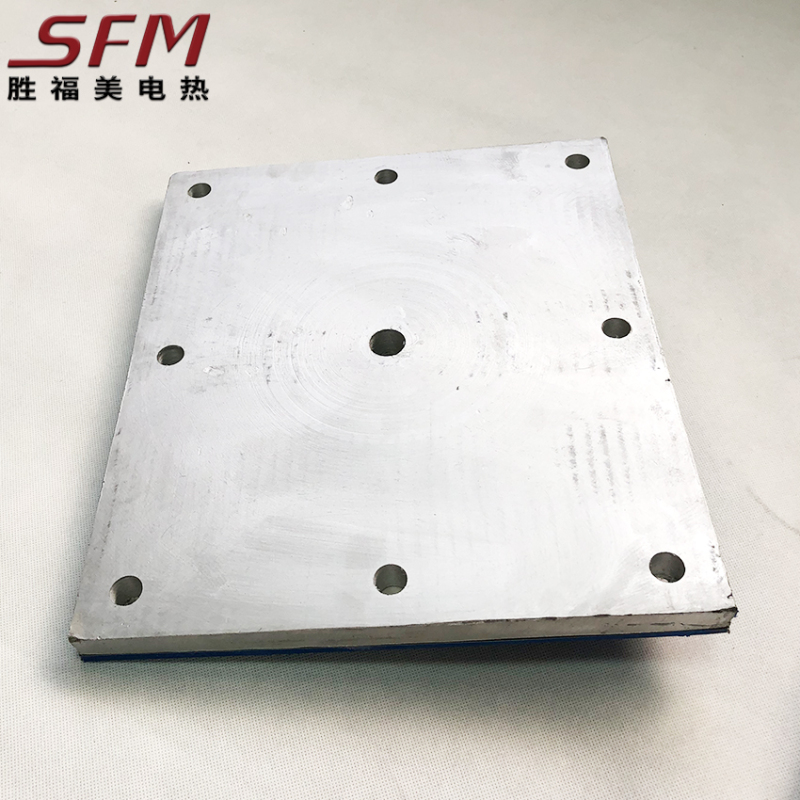

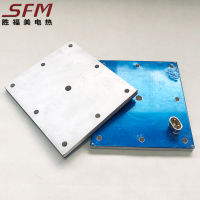

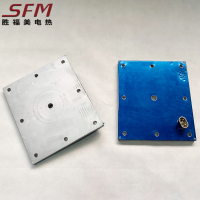

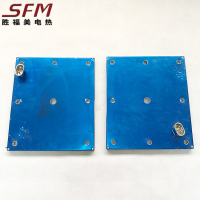

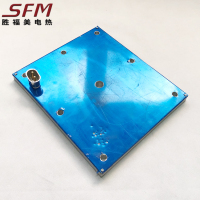

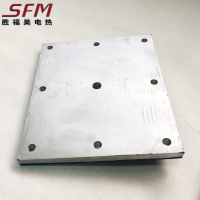

Thickness 30MM Cast aluminum Plate Heater

Cast-In Aluminum Heaters are an essential component for all plastics extrusion machinery. Cast-In Aluminum Heaters are made of aluminum or bronze. Stringent machining tolerances on the inside working surface and high quality heating element construction guarantee high performance

- SFM

- china

- 12-15 day

- Information

Cast Aluminum Heater Description:

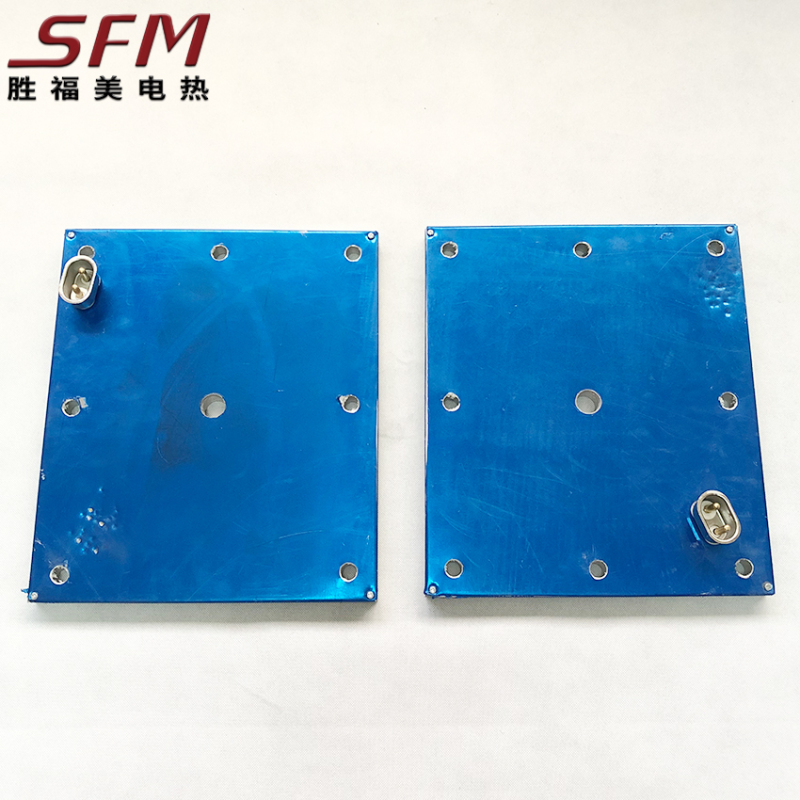

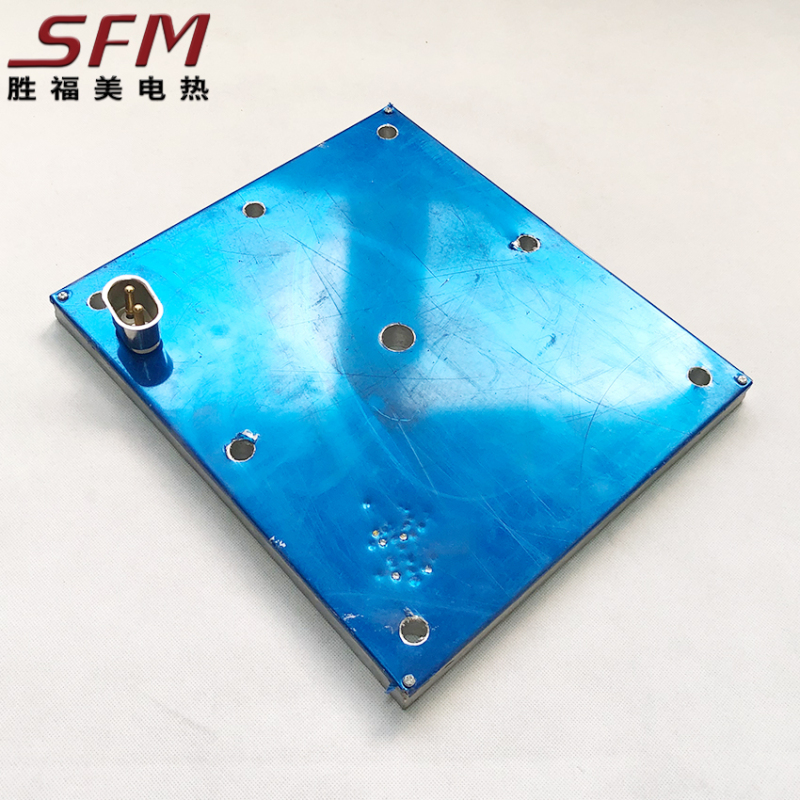

Cast in aluminum heater is mainly used for extrusion and casting moulding machines. It has a wide application in various machinery industries. The operation temperature can reach up to 300°C -400°C(Aluminium). In order to concentrate the heat to one direction on the injection face, the other sides of the product are covered by heat retention and heat insulation materials. So it has advantages such as advanced technology, high heat retention, long lifetime, anti-pollution, etc. It is widely used in plastic extrusion, chemical fibre, blowing moulding machines

Product Name | Die Casting Aluminum Plate Heater |

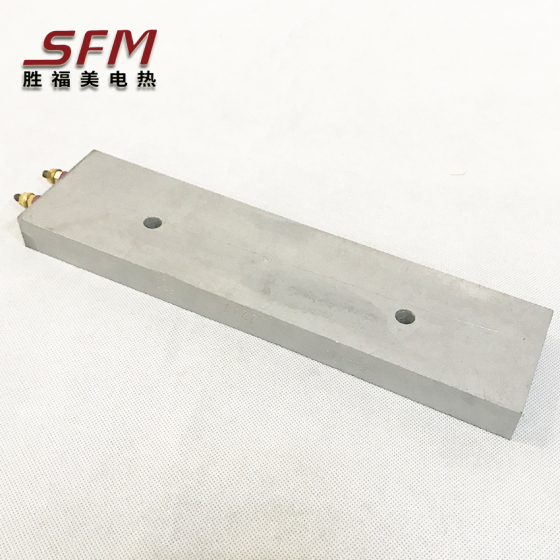

Thickness | 20mm, 30mm, 35mm, or customized |

Working Temperature | Normal temperature 350 degree,max 400 degree |

Voltage | 120V, 240V, 480V, 600V or customized |

Power | 50-2000W, or customized |

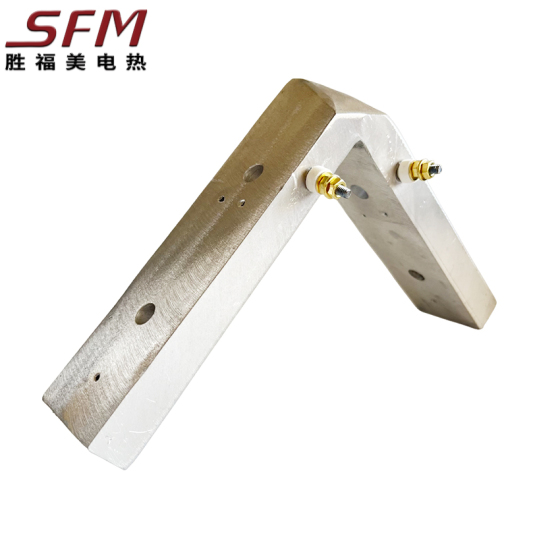

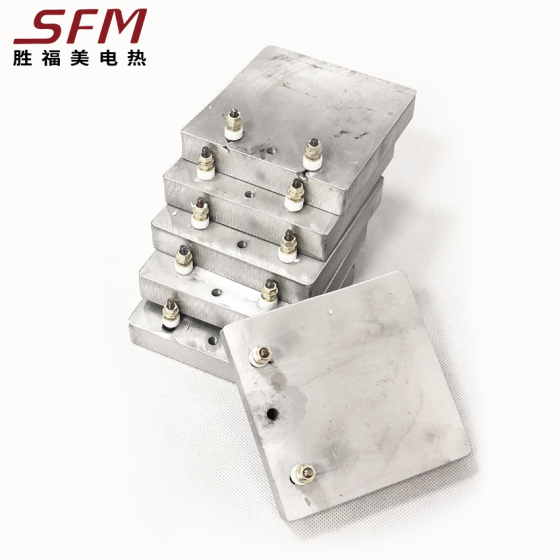

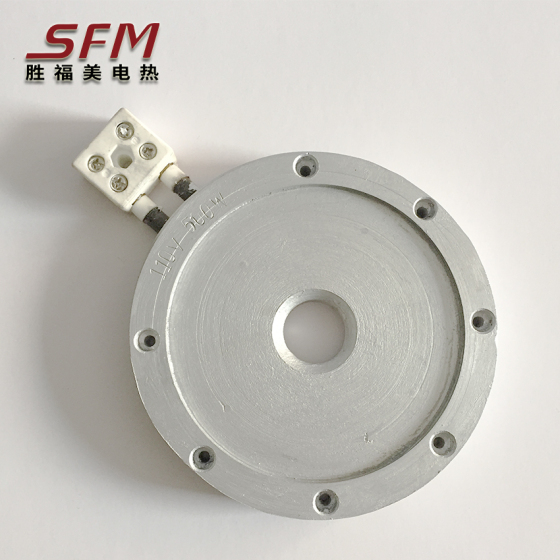

Shape | round, flat, rectangular, square,air-cooled, water-cooled and other shapes |

Wattage Tolerance | +5%, -10% |

Resistance tolerance | +10%, -5% |

Leakage current | <0.5MA |

Insulation resistance | > 2MΩ |

Material | Aluminum, brass, bronze or cupronickel alloy |

Advantages:

Aluminum-casting heater is a kind of high efficiency Heater with uniform heat division, and Metal alloy with excellent thermal conductivity, to ensure the hot surface temperature uniformity, reducing the temperature difference between surface of device. It has the advantages of long life, good thermal insulation performance, strong mechanical properties, corrosion resistance and magnetic resistance etc.. Increasing the heat dissipation device on the outer heat dissipation surface and sintering infrared rays on the inner heat dissipation surface can save electricity by 35%

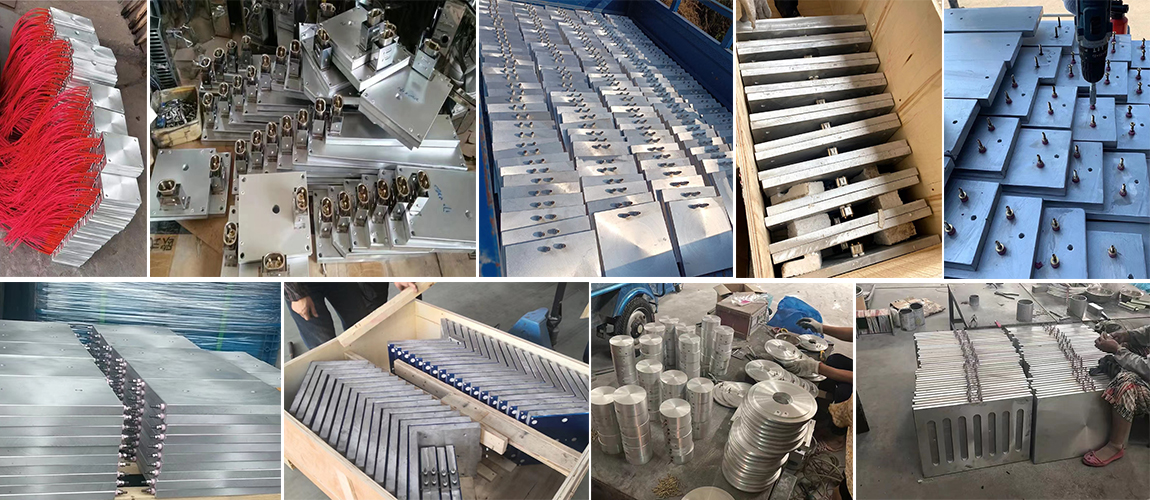

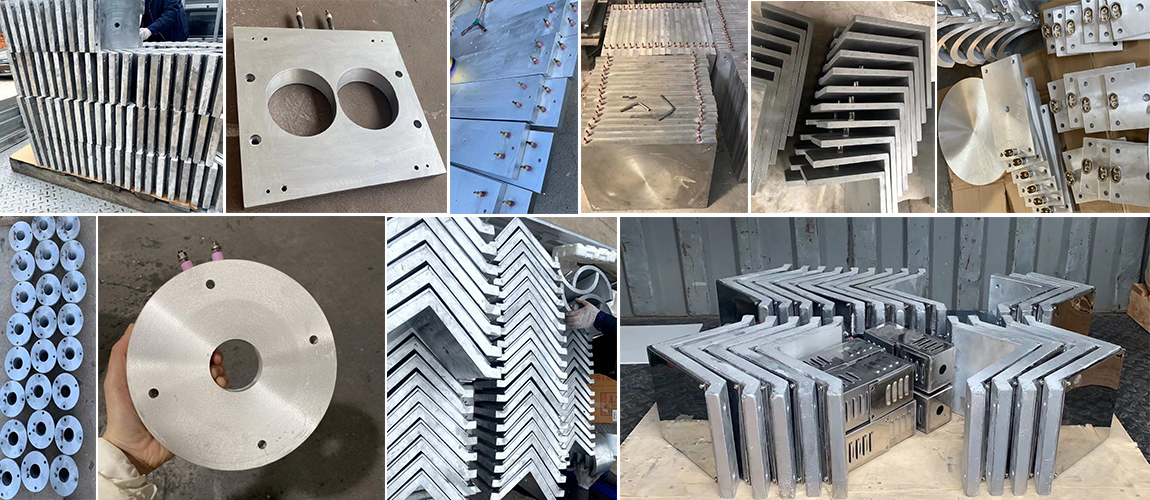

Cast In heaters for all plastics processing applications including, air and liquid cooled barrel heaters, L-shaped heaters, vent cut out heaters, heat only cast in barrel heaters, air cooled with shroud, hollow cast nozzle heaters, and cooling jackets for cast in barrel heaters.

Cast band heaters (Cast-in) are available in Aluminium (300-400ºC), Brass (600ºC) and Bronze (700ºC). Cast aluminium water-cooled units are the most common. The casting contains both Incoloy sheathed heating elements and stainless steel cooling tubes. The heaters are available with bolt clamping or separate stainless steel strap clamping. Heating elements are supplied standard with threaded stud terminals for electrical connections. Sheet metal terminal boxes and other termination options are available.

Order Guide

Please specify the following when ordering.

1:The inner length (mm) and width (mm) of heaters

2:Thickness of heaters

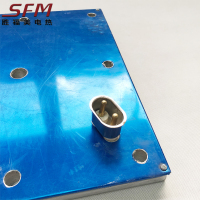

3:Terminal length (max & min) and the distance of terminal length

4:The diameter, length of cooling tubes and the distance between them.

5:Voltage and power density

6:Gap of two pieces if applicable

7:Wiring type and position

8:Content of the stamping if needed

9:Order quantity

10:Delivery date

** It’s better to provide us with the drawings/pictures

Others: position of terminal box, the position and size of the hole for connecting thermocouple OR of the incision, whether need to cast in the terminal