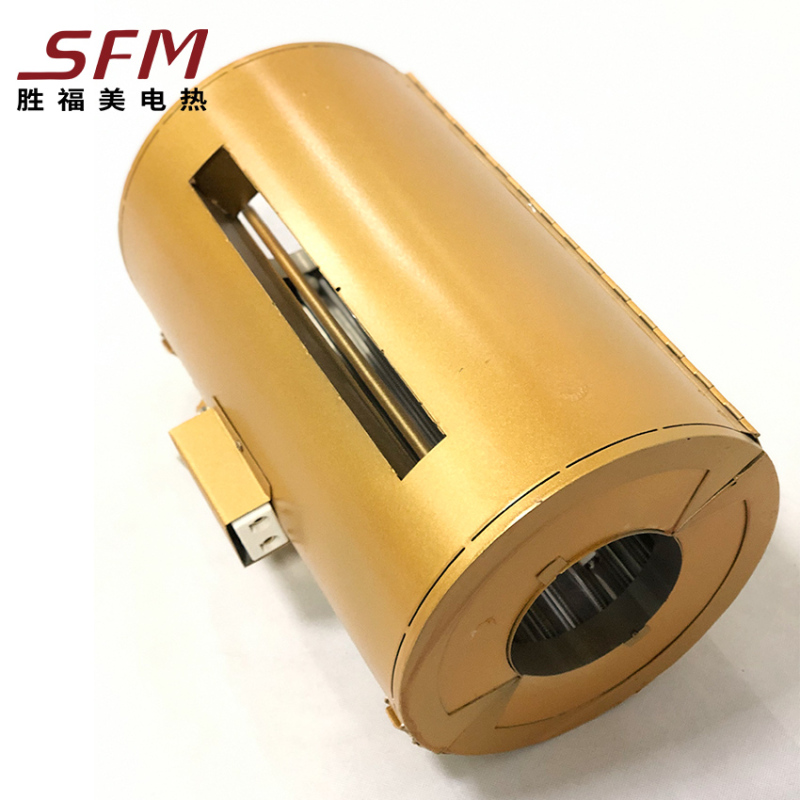

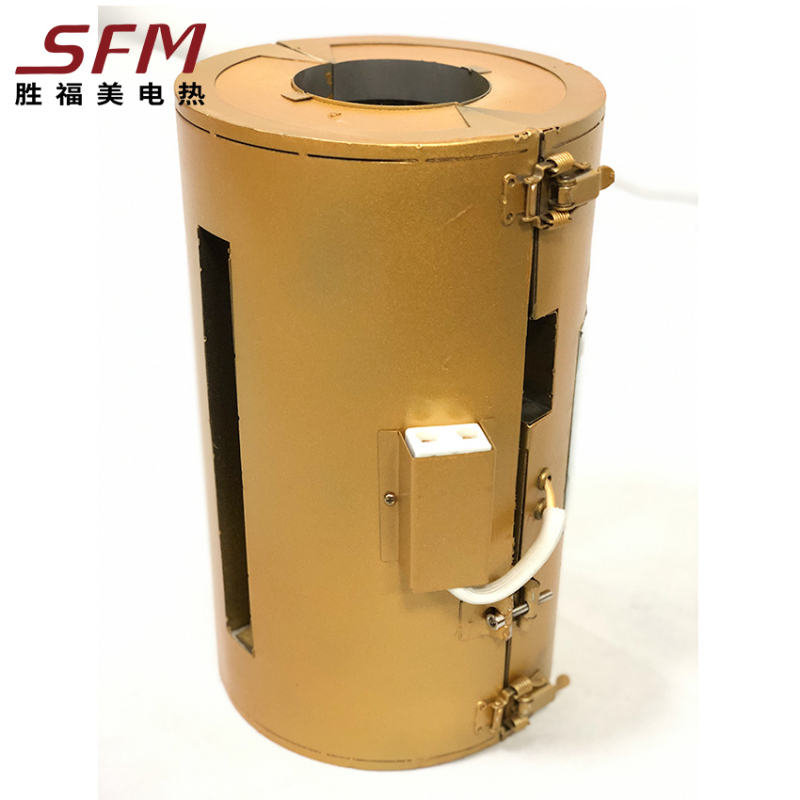

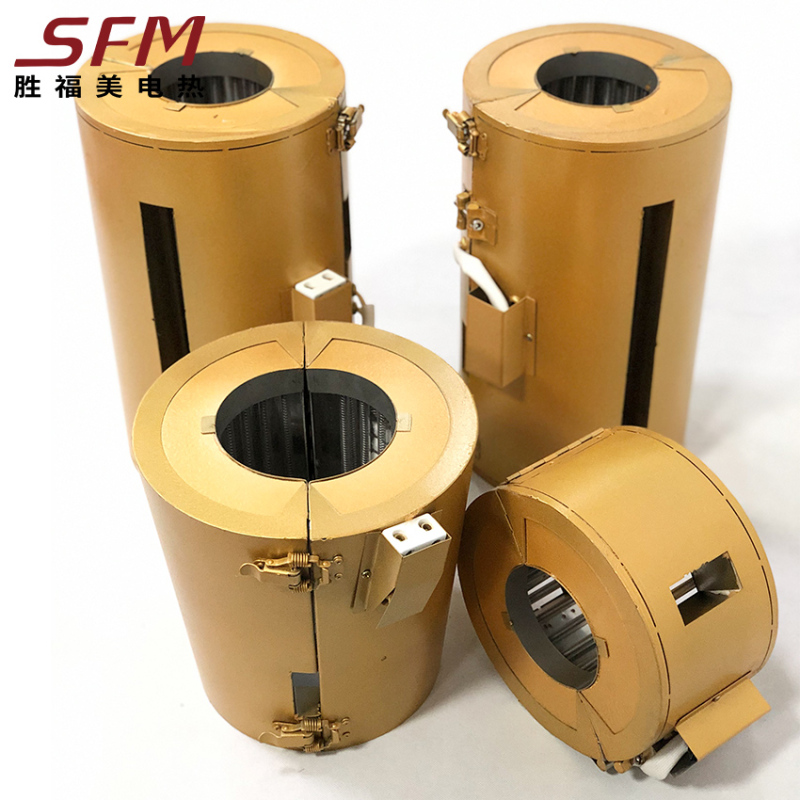

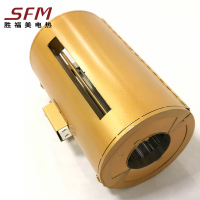

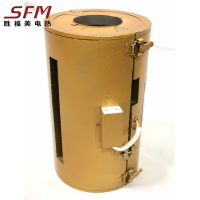

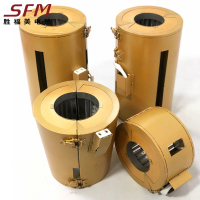

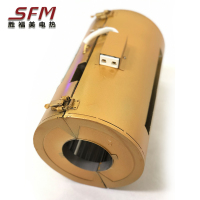

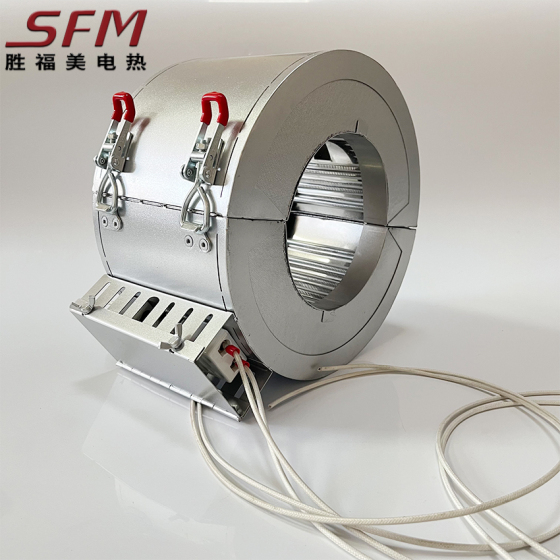

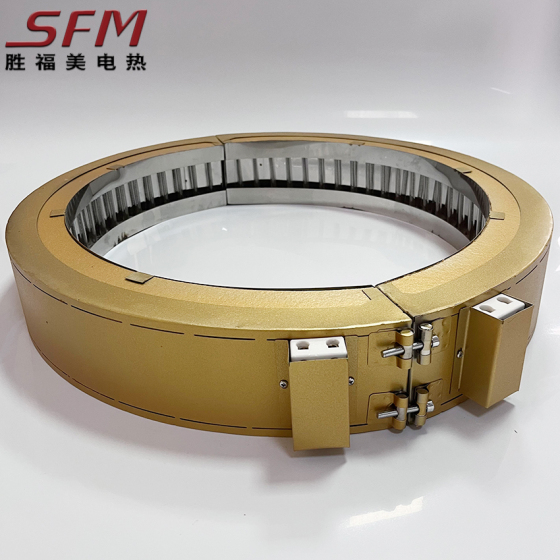

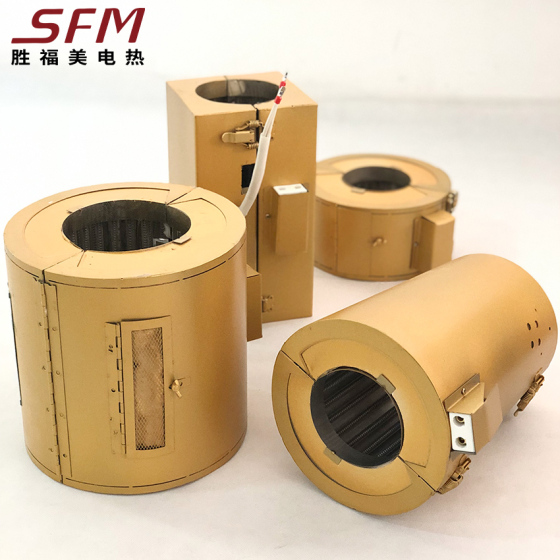

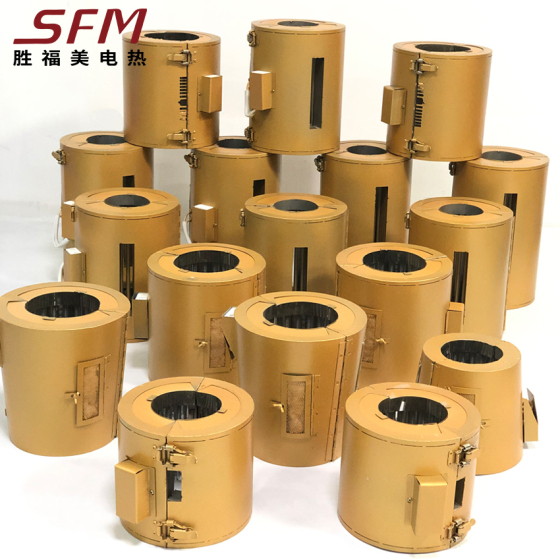

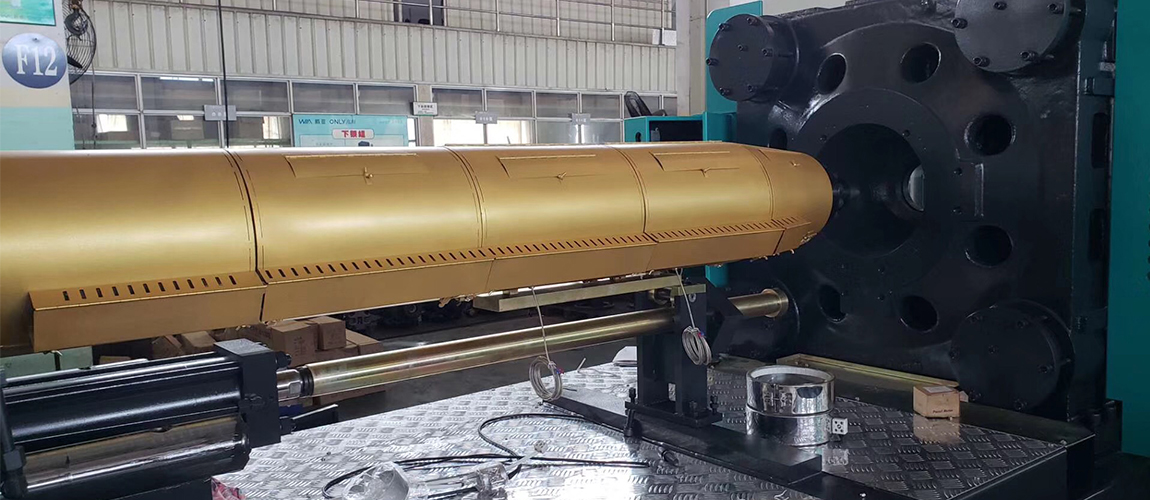

Heater Dc Electric Infrared Nano Heater Band

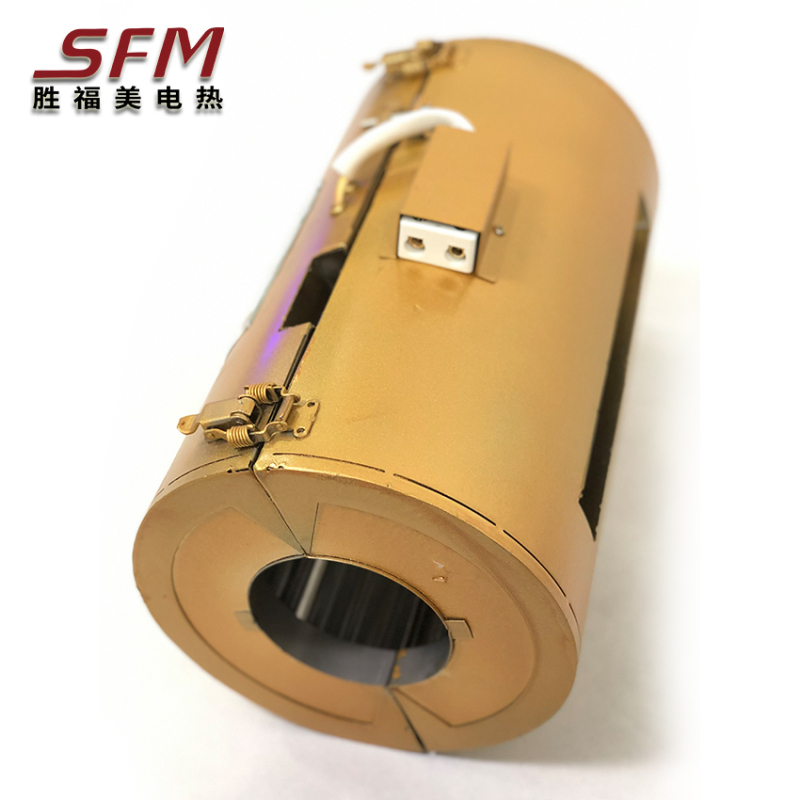

Nano far-infrared electric band heater is heated by the high resistance electric heating wire and far-infrared ray, which generate through quartz far infrared radiation tube. It is normally used in the plastic processing machinery. The electric heating ring has the advantages of high thermal efficiency, good energy-saving effect and low surface temperature.It is the most advanced heaters for the injection molding machine industry

- SFM

- China

- 5-8 day

- Information

Description:

Description:

1:Nano-infrared energy-saving electric heater adopts a new type of polymer nano-heating alloy, and the heating efficiency of the heating element is up to 99.8%;

2:nano-infrared energy-saving electric heater adopts infrared heat transfer method.

3:Nano-infrared is not only heats up quickly, but also has good heat preservation effect, and the surface temperature of the electric band heater is only 45-75 °C, which has little influence on the ambient temperature and can effectively reduce the room temperature of the working workshop.

4 :nano-infrared energy-saving electric heating ring is simple and convenient to install, can

be directly used to replace the traditional electric heating circle 5 Product reliability is high, energy saving and environmental protection, energy saving rate is as high as 30%-80%, and all investment recovery time is about 3-9 months

Industrial nano infrared band heater for injection molding machine advantages

1. Improve electro thermal conversion rate – over 99.8% (nano carbon silicon material) .

2. Improve heat transmission efficiency (zero medium heat radiation, specific wave length infrared radiation).

3. Reduce heat loss (thick nano insulation layer).

4. Energy-saving rate: 30%-80%.

5. Surface temperature is around 50℃- significantly improves workshop environment.

6. Simple installation – just like installing normal resistance heaters.

7. SUS cover which is stable and long usage life.

Industrial nano infrared band heater for injection molding machine

Insulations | 1430 Ceramic Fiber Mat + Nano Material + Airgel |

Install fan

| with or without

|

Reflective layer

| Mirror 323 stainless steel plate

|

Project

| 5th generation nano heating coil

|

Shell

| 304 stainless steel plate + double-sided plating

|

Shell coating

| High temperature coating

|

Nano coating

| Titanium dioxide nano coating

|

Heating element

| Swedish import of nano alloy wire

|

Exterior color

| Silver / Gold

|

Far infrared components | Transparent infrared tube |

Shengfumei Heat Technology Co., Ltd. Nano -Energy -saving heater Case | ||||

Case 1: | ||||

No.Of Machinery | ||||

No.Of Machinery | Electricity before Use NanoHeater | Electricity after Use NanoHeater | Save Electricity | Rate of Saving Electricity |

#30 | 16.5° | 10.8° | 5.7° | 35% |

Cost save: | ||||

Electricity Every Day Per Machinery | Save Electricity Per Machinery | Save Cost Per Machinery | Save Cost Per Machinery Per Year | |

136.8° | 4104° | RMB4104(us$630.0) | RMB49248(us$7500.0) | |

Case 2: | ||||

Machinery: Haitian350T Injection Machinery | ||||

No.Of Machinery | Electricity before Use Nano Heater | Electricity after Use Nano Heater | Save Electricity | Rate of Saving Electricity |

#20 | 6.8° | 3.1° | 3.7° | 53% |

Cost save: | ||||

Electricity Every Day Per Machinery | Save Electricity Per Machinery | Save Cost Per Machinery | Save Cost Per Machinery Per Year | |

88.8° | 2664° | RMB2664(us$410.0) | RMB31968(us$4900.0) | |