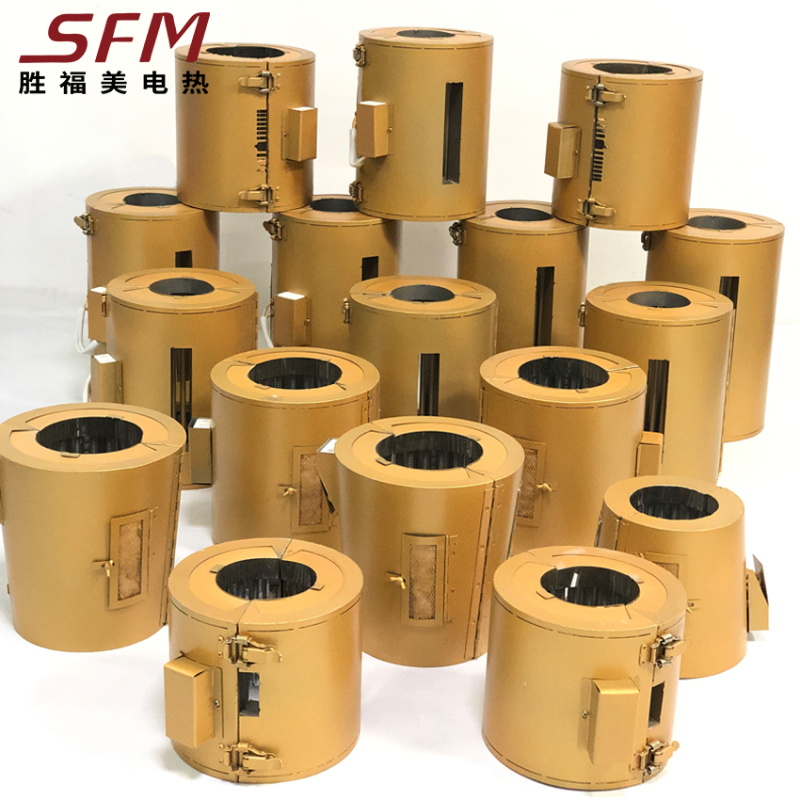

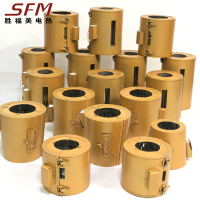

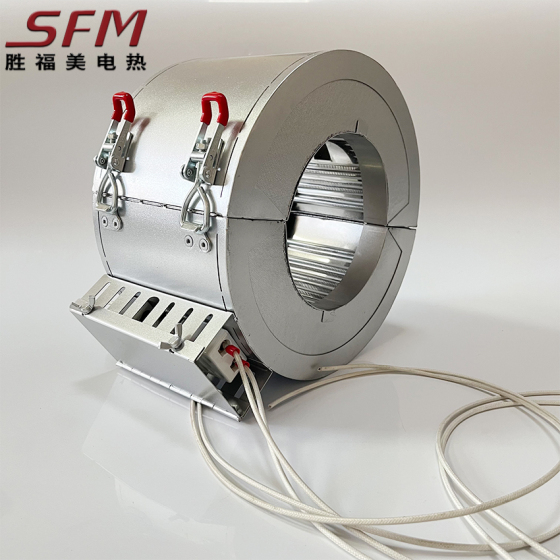

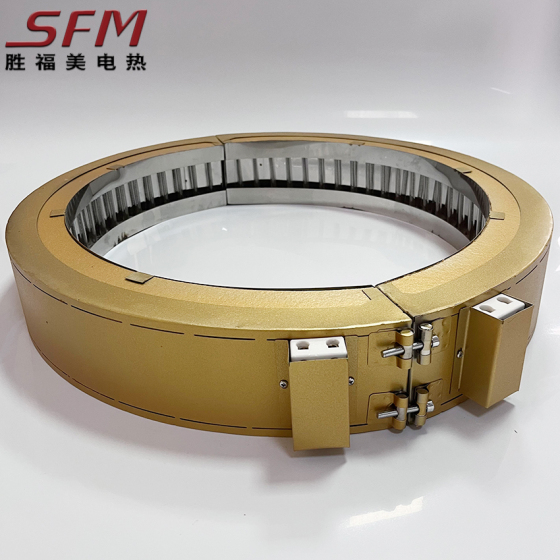

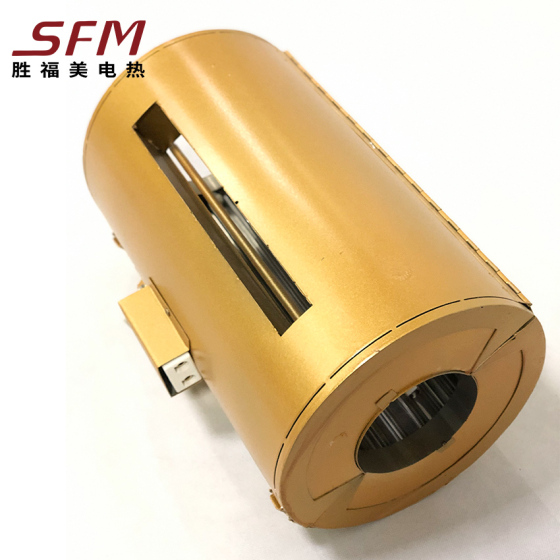

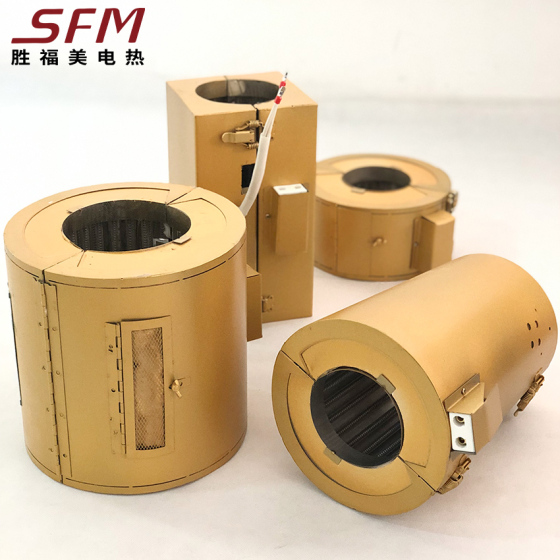

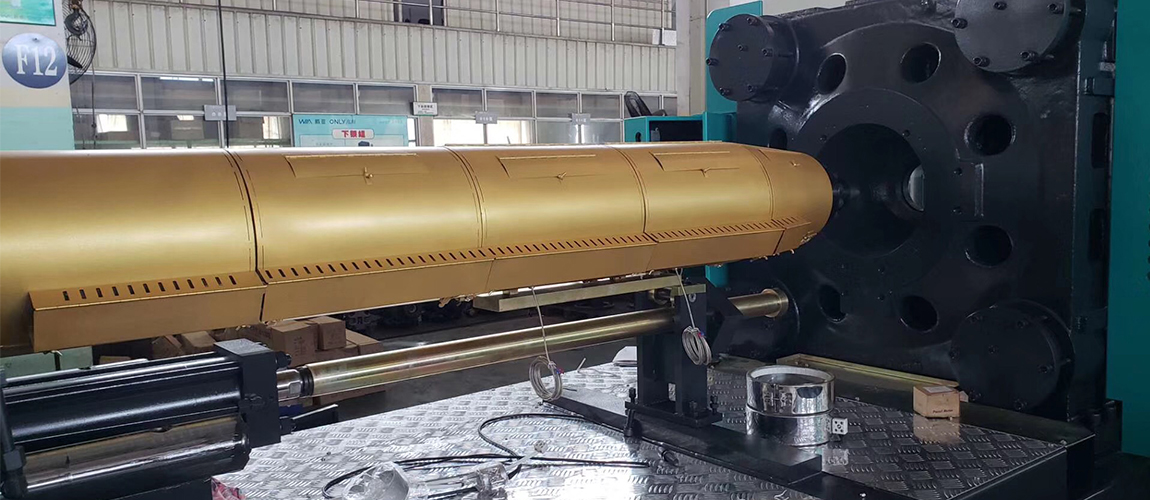

Nano Band Infrared Heater For Pelleting Machine

1.Electric heating conversion efficiency is 99.8%;

2.Infrared radiation heating mode, high efficiency and unidirectional radiation;

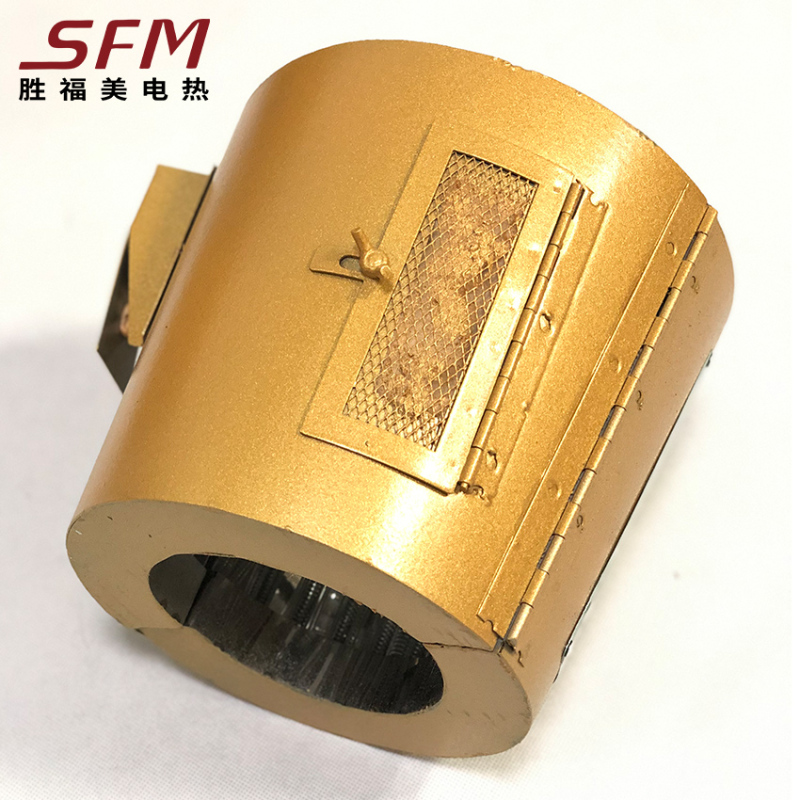

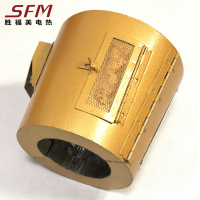

3.Surface temperature is lower than 70 degrees, greatly improving the operating environment;

4. Energy saving rate as high as 30%-83%;

5.Installation is simple, can be directly replaced the existing electric heating circle;

6.Operation safety

- SFM

- China

- 5-8 day

- Information

Description:

Description:

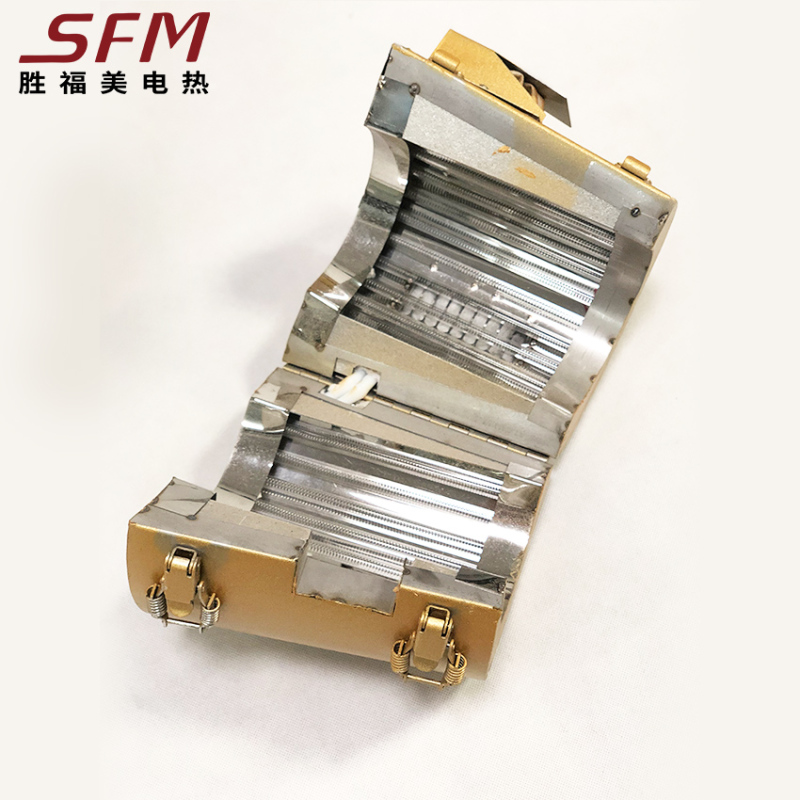

1:Nano-infrared energy-saving electric heater adopts a new type of polymer nano-heating alloy, and the heating efficiency of the heating element is up to 99.8%;

2:nano-infrared energy-saving electric heater adopts infrared heat transfer method.

3:Nano-infrared is not only heats up quickly, but also has good heat preservation effect, and the surface temperature of the electric band heater is only 45-75 °C, which has little influence on the ambient temperature and can effectively reduce the room temperature of the working workshop.

4 :nano-infrared energy-saving electric heating ring is simple and convenient to install, can

be directly used to replace the traditional electric heating circle 5 Product reliability is high, energy saving and environmental protection, energy saving rate is as high as 30%-80%, and all investment recovery time is about 3-9 months

Industrial nano infrared band heater for injection molding machine advantages

1. Improve electro thermal conversion rate – over 99.8% (nano carbon silicon material) .

2. Improve heat transmission efficiency (zero medium heat radiation, specific wave length infrared radiation).

3. Reduce heat loss (thick nano insulation layer).

4. Energy-saving rate: 30%-80%.

5. Surface temperature is around 50℃- significantly improves workshop environment.

6. Simple installation – just like installing normal resistance heaters.

7. SUS cover which is stable and long usage life.

Industrial nano infrared band heater for injection molding machine

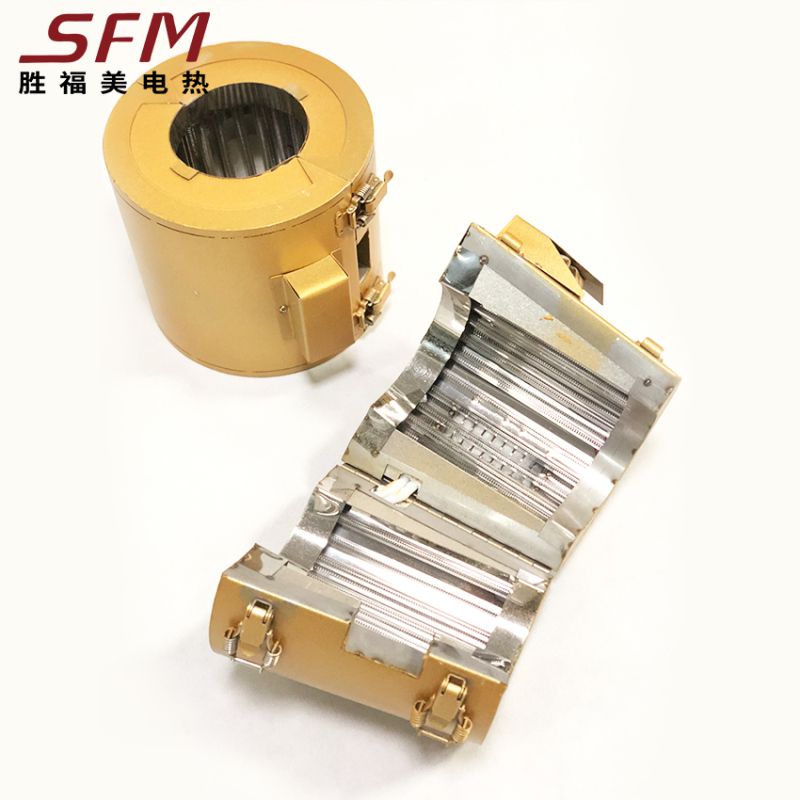

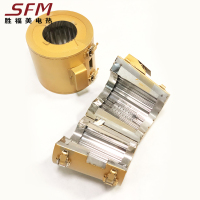

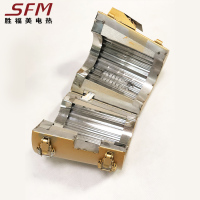

Insulations | 1430 Ceramic Fiber Mat + Nano Material + Airgel |

Install fan

| with or without

|

Reflective layer

| Mirror 323 stainless steel plate

|

Project

| 5th generation nano heating coil

|

Shell

| 304 stainless steel plate + double-sided plating

|

Shell coating

| High temperature coating

|

Nano coating

| Titanium dioxide nano coating

|

Heating element

| Swedish import of nano alloy wire

|

Exterior color

| Silver / Gold

|

Far infrared components | Transparent infrared tube |

Shengfumei Heat Technology Co., Ltd. Nano -Energy -saving heater Case | ||||

Case 1: | ||||

No.Of Machinery | ||||

No.Of Machinery | Electricity before Use NanoHeater | Electricity after Use NanoHeater | Save Electricity | Rate of Saving Electricity |

#30 | 16.5° | 10.8° | 5.7° | 35% |

Cost save: | ||||

Electricity Every Day Per Machinery | Save Electricity Per Machinery | Save Cost Per Machinery | Save Cost Per Machinery Per Year | |

136.8° | 4104° | RMB4104(us$630.0) | RMB49248(us$7500.0) | |

Case 2: | ||||

Machinery: Haitian350T Injection Machinery | ||||

No.Of Machinery | Electricity before Use Nano Heater | Electricity after Use Nano Heater | Save Electricity | Rate of Saving Electricity |

#20 | 6.8° | 3.1° | 3.7° | 53% |

Cost save: | ||||

Electricity Every Day Per Machinery | Save Electricity Per Machinery | Save Cost Per Machinery | Save Cost Per Machinery Per Year | |

88.8° | 2664° | RMB2664(us$410.0) | RMB31968(us$4900.0) | |