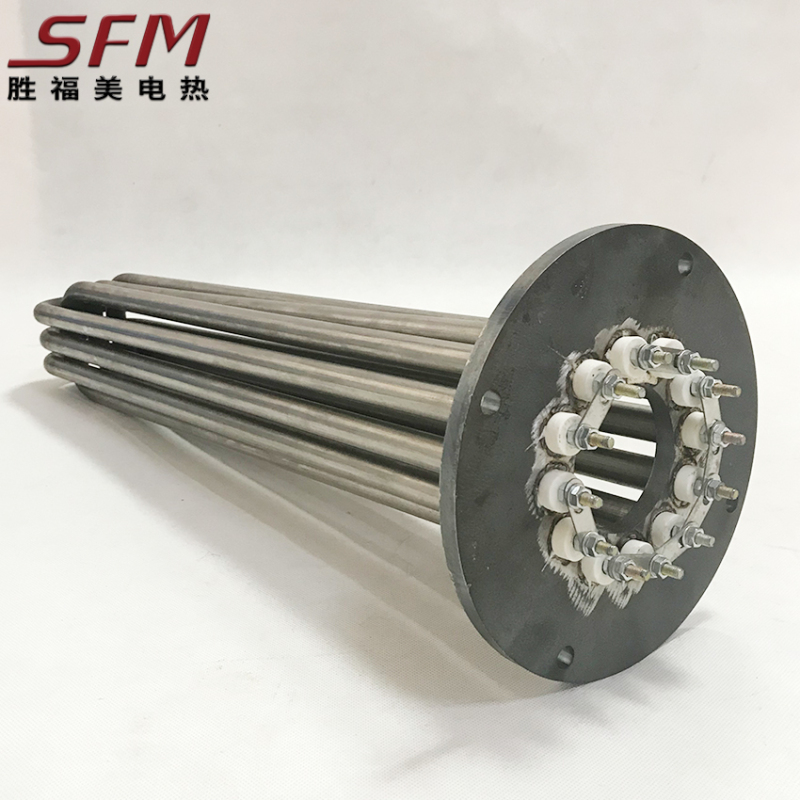

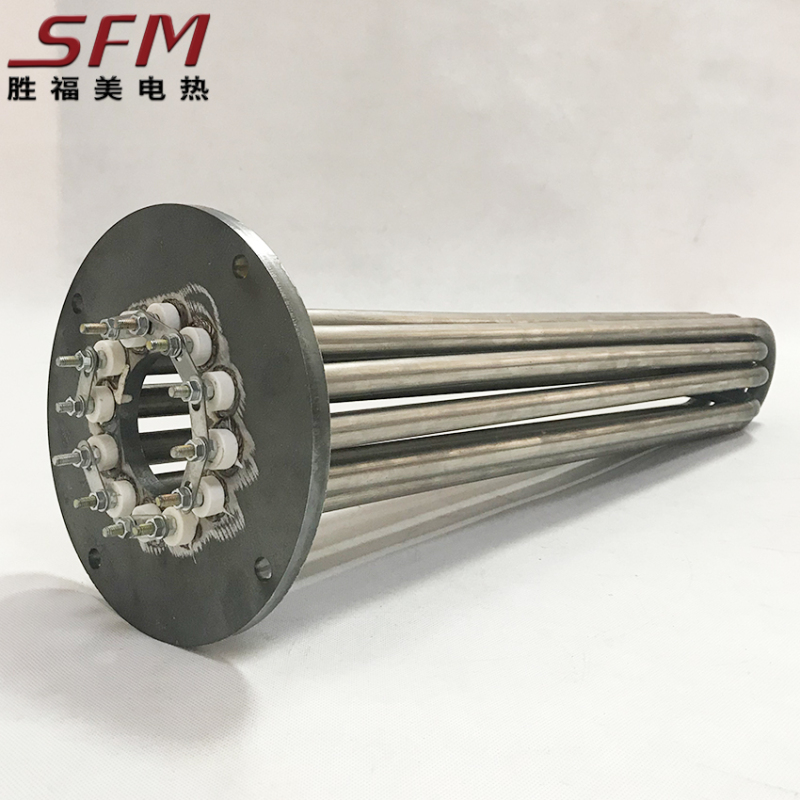

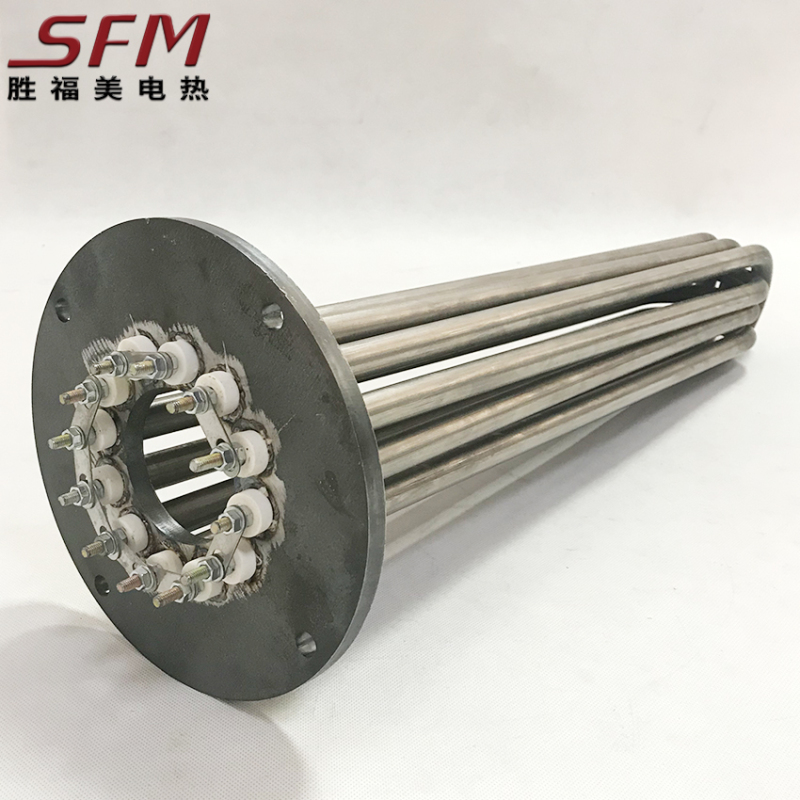

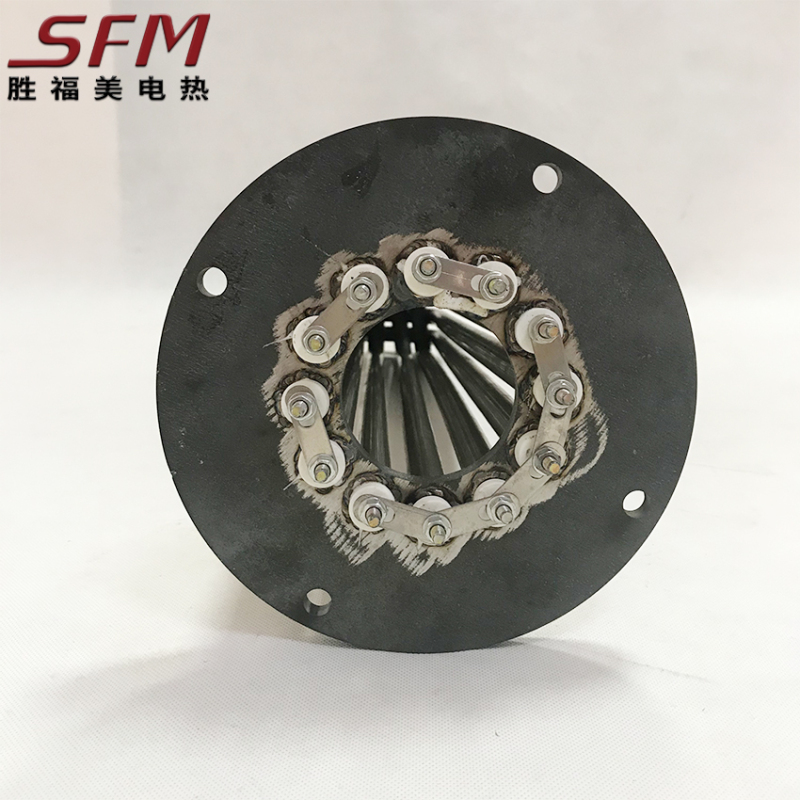

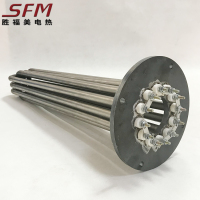

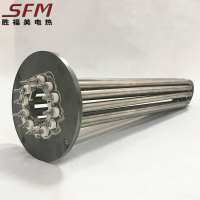

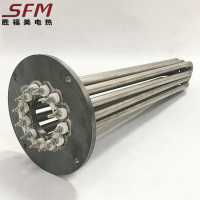

Industrial Tubular Immersion Type Round Flange Heater

Immersion Heater are custom designed in a various shapes to as client's requirements for direct immersion in liquids such as water, oils, solvents and process solutions, molten materials as well as air and gases.

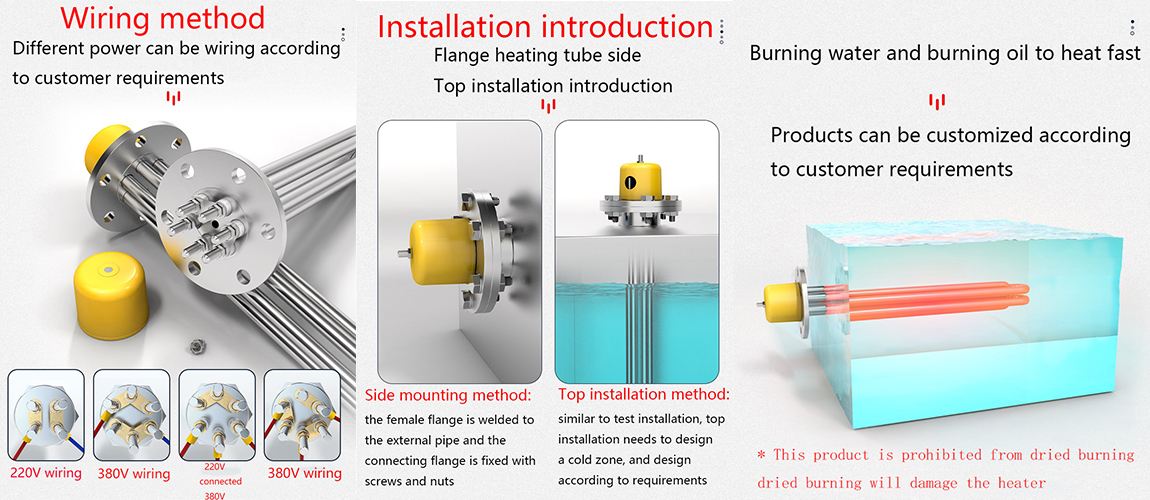

*Tubular heaters are produced using Incoloy, stainless steel or Copper sheath materials and also there is huge variety of selection of termination styles available. Insulation of Magnesium offers greater heat transfer.

*Tubular heaters can be used in any application. Straight tubular can be inserted in machined groves for conductive heat transfer and formed Tubular provides consistent heat in any type of special application.

- SFM

- China

- 7-9 day

- Information

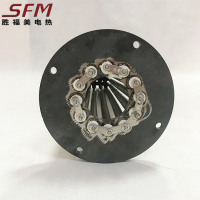

FLANGE HEATERS

FLANGE HEATERS

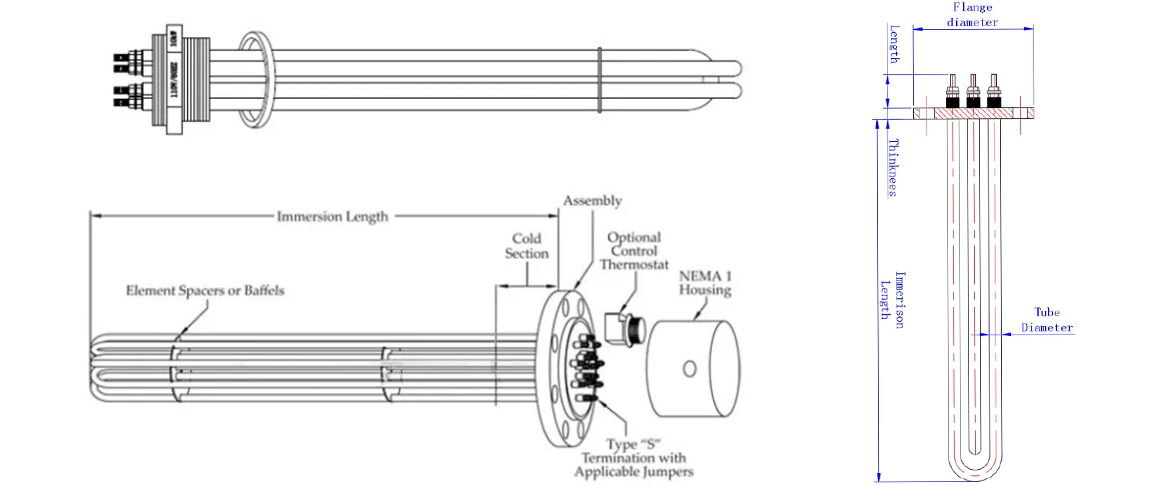

Mounted on the side of tanks, it is extremely strong and provides excellent heat. Flange plate size, thickness and shape are determined by the application.

OVER THE SIDE HEATERS

A practical method of heating open tanks from the top (typically). It offers the ability to use this heater for multiple tanks while other immersion heaters can't be conveniently installed.

SCREW PLUG HEATERS

These heaters screw into your tank and provide heat to liquids in smaller tanks and compartments. They are installed into threaded openings or couplings in the tank or vessel.

CORROSIVE LIQUID HEATERS

Corrosion resistant sheath materials and special surface treatment are available so the heaters could be used in corrosive environments and have longer service life.

THERMO CONTROL

In order to achieve temperature control, overheat protection and longer life of the heaters, a thermostat or thermocouple could be integrated into the heaters.

CUSTOM NON-HEATING PARTS

No-heat parts could be customized for different applications.

Technical Parameters | |

Tube Diameter | Φ6mm ~ Φ67mm |

Voltage | 110V/220V/230V/240V/380V/415V |

Power | 1kW ~ 120kW |

Watt Density | 30W/cm² |

Wattage Tolerance | +5%, -10% |

Length Tolerance | ±1.5% |

Resistance Wire | Nickel chromium resistance wire (Ni80Cr20) |

Sheath Materials | Copper, Titanium, 304 Stainless Steel, 310 Stainless Steel, 316 Stainless Steel, Incoloy 800, Incoloy840 |

Surface Treatment | Polishing, coating, plating |

Sheath Materials | |

Sheath Materials | Application |

Copper | Water, non-corrosive liquids |

Stainless Steel | (304,310,316):Process water, corrosive liquids, oils, acid, alcaline baths, asphalt, wax, heavy fuel, food processing equipment

|

Incoloy (800, 840) | Water, oils, asphalt, wax, heavy fuel |

Titanium | Highly corrosive liquids |

Features

1. Virtually 100% energy efficient

2. Provide uniform temperature

3. Can be formed and shaped into various geometries

4. Easy to install, remove and maintain

5. Oxidation and corrosion resistant

6.Durable

Design Details

Please provide the following information:

1. Heating medium and operating temperature

2. Voltage and phase

3. Rating power

4. Mounting method

5. Sheath material

6. Detail dimensions

7. With or without temperature control

Note:The more details provided, the better it'll be designed and fits the application