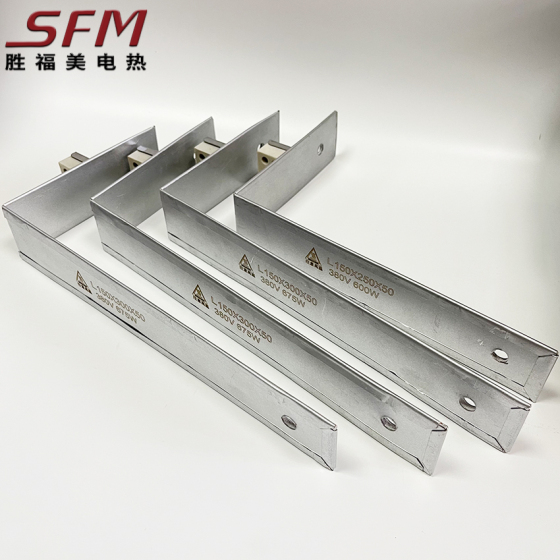

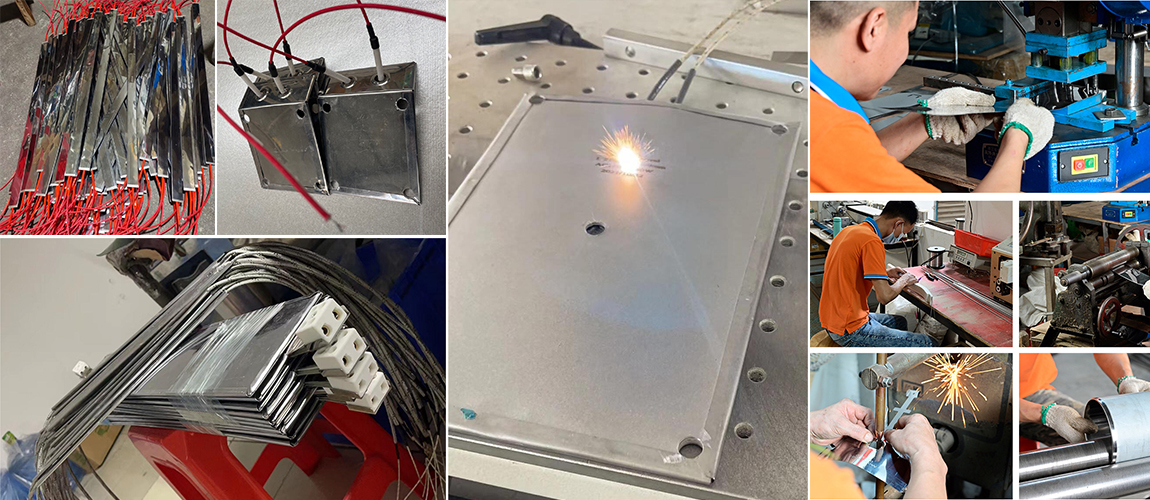

Mica Plate Heater With Ceramic Terminal

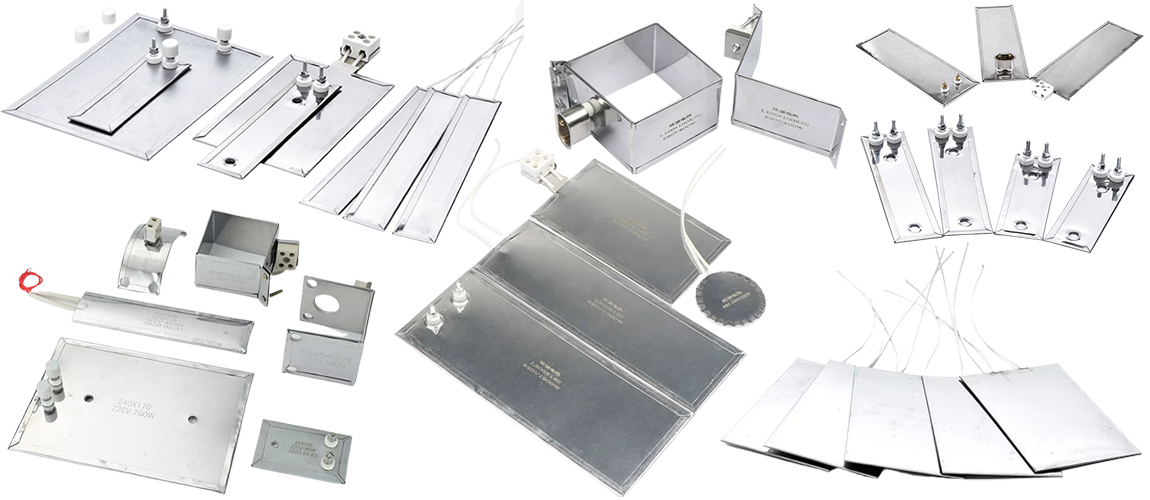

Mica plate Heater For Extruder 1. Mica plate Heater-2 pieces 2.Mica plate Heater- 1 piece (with metal strip) 3. Mica plate Heater-with holes 4. Mica plate Heater- with thermocouple bracket 5.Mica plate Heater-partial coverage model 6. Mica plate Heater- with hinged construction post terminals

- SFM

- China

- 2-7 day

- Information

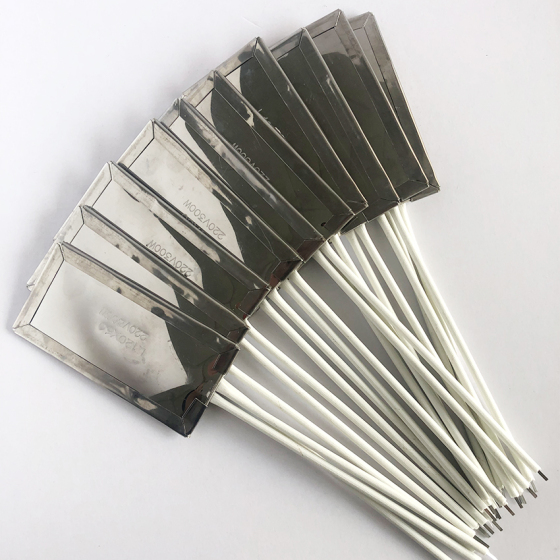

NON-STANDARD LOCATION OF LEADS OR TERMINALS

Terminations could be offset, paralleled, centered, or at each end. Lead wires are available.

Leads or terminals may be located at any reasonable place along the heater for applications where standard connections may be inaccessible.

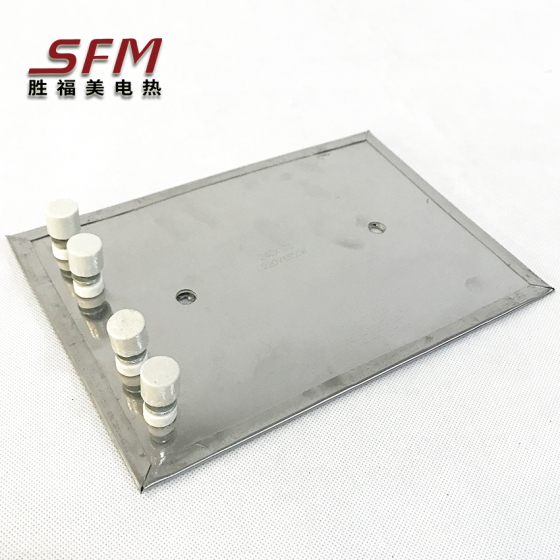

HOLES AND CUTOUTS

Mounting holes locations could be customized. Please provide drawing for hole dimensions and locations.

Technical Parameters | |

Voltage: | 110V/220V/230V/240V/380V |

Power: | Can be customized |

Wattage: | Up to 3W/cm2 |

Wattage Tolerance : | +5%, -10% |

Temperature: | 300-600℃ |

Sheath Thickness: | Can be customized |

Insulation Resistance: | ≥100 MΩ |

Main Materials | |

Sheath Material | Stainless steel |

Resistance Wire | Nickel Chromium (Ni80Cr20) |

Insulation | Mica |

Lead Wire | With protective sleeve, steel hose or braid |

Terminal | Thread, ceramic, metal box, plug |

Features

1. Easy and economical to install

2. Available in a wide range of wattages & voltages

3. Uniform heat distribution

4. Ribbon resistance offers broad surface contact for extended life

5. Could be used single or in groups to provide the required amount of heat

6. Flexible in shape design to fit applications

7. Durable

Design Details

Please provide the following information:

1. Operating temperature

2. Voltage and phase

3. Rating power

4. Termination types

5. Mounting method

6. Detail dimensions

7. Holes and cutouts position

Note:The more details provided, the better it'll be designed and fits the application