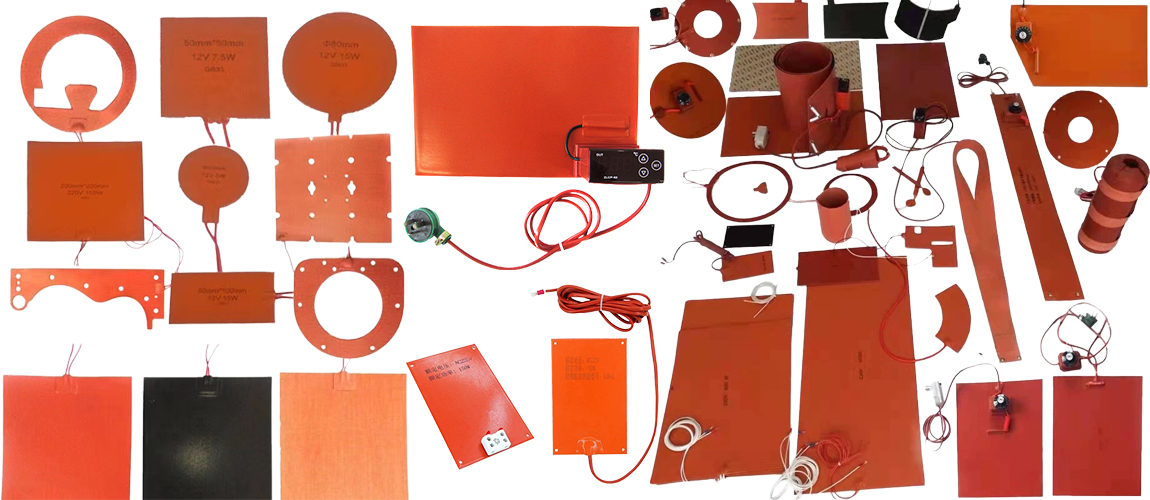

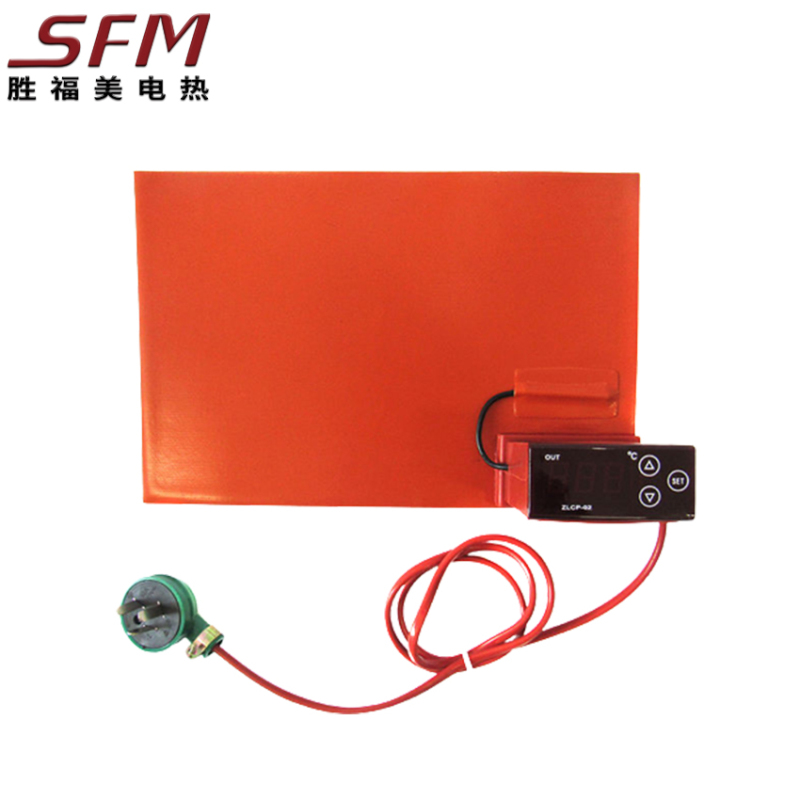

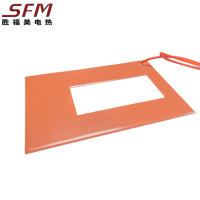

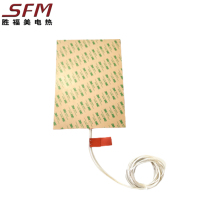

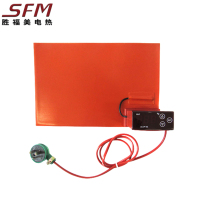

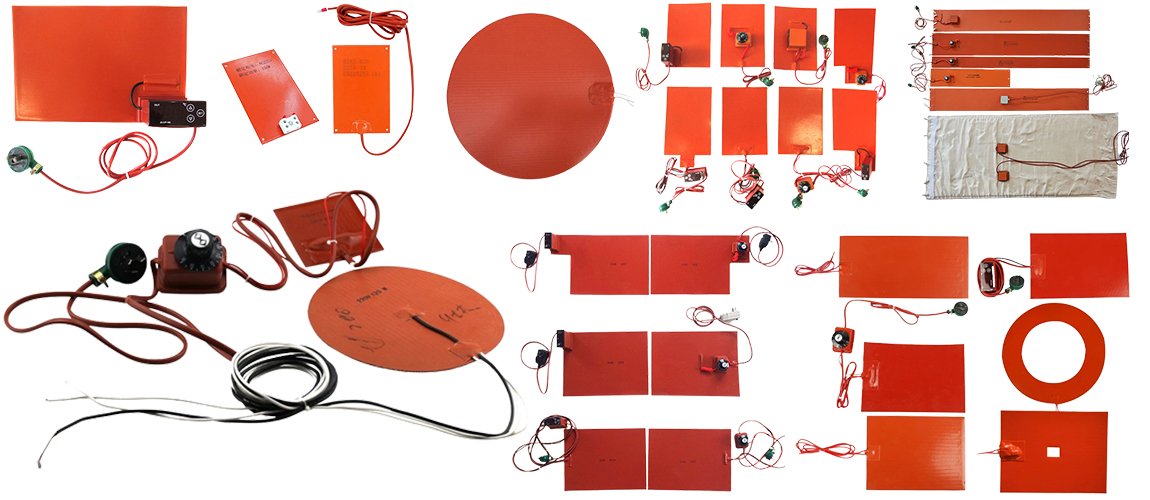

Silicone Heating Pad Based Heating Wire

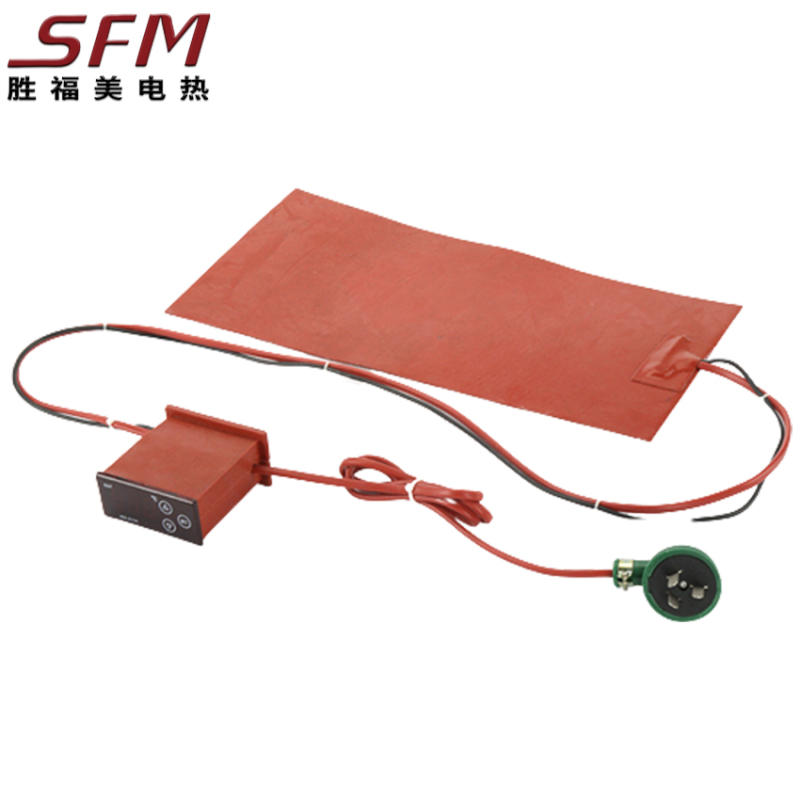

1)The maximum temperature resistance of the insulating material:250℃

2)Highest service temperature:250℃-300℃

3)Insulating resistance:≥50MΩ

4)Compressive strength:1500v/5s

5)Power deviation rate:±5%

6)High Voltage resistance:>5KV

- Information

Product Description

Name | Silicone rubber heater |

Electric resistance precision | ±10%( bigger value selected) |

Power deviation | 5% |

Mechanical pressure | 100.00kg/cm² |

Minimum bending radius | 3.20mm |

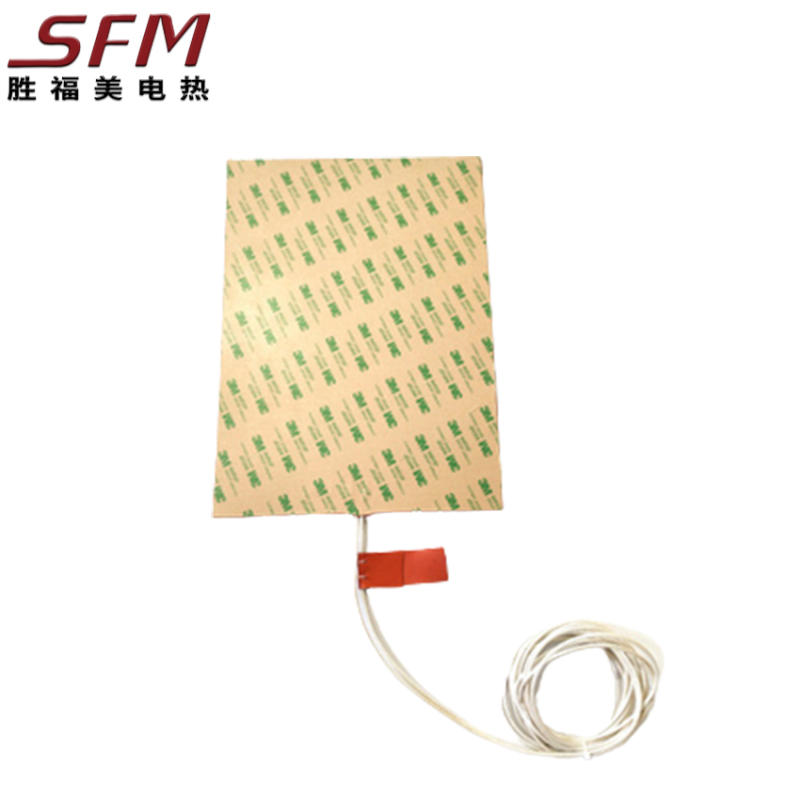

External insulation material | Silicone glass fiber |

Internal heating element | Ni-Cr alloy |

Thickness | 1~1.5mm(0.039"~0.059") |

Voltage range | 1.5-660V |

Power density range | 0.03w/cm2~2.5w/cm2 (0.19w/inch2~16.13w/inch2) |

Using temperature range | -60~250°C (-140~482°F) |

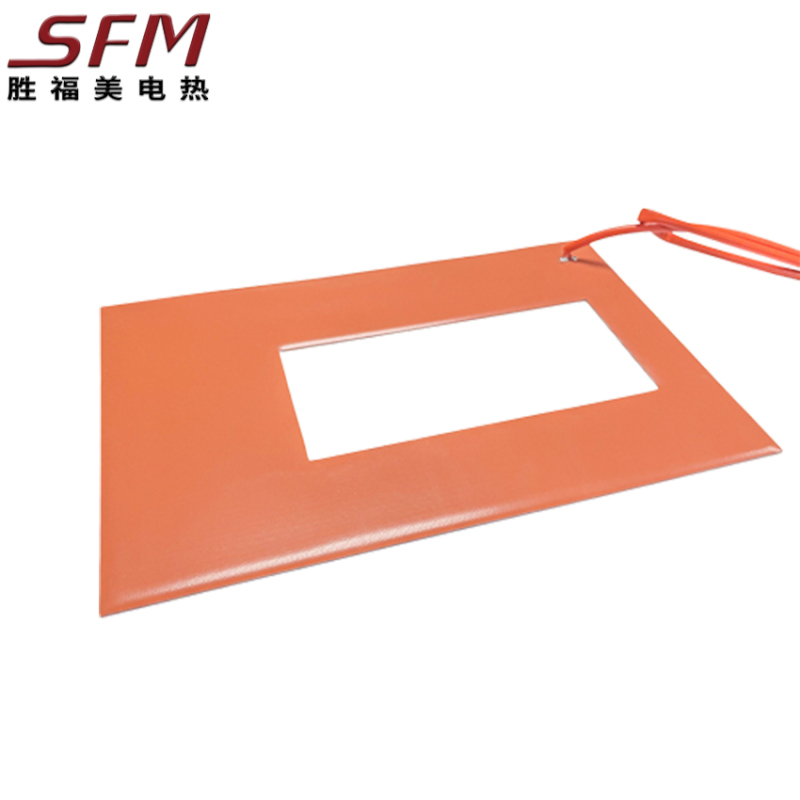

Width range | 10mm~1200mm (0.39"~47.24") |

Length range | 10mm~10000mm(0.39"~393.7") |

Product Advantage

Features for silicone rubber heater

1.Maximum temperature resistant of insulant: 300°C

2.Insulating resistance: ≥ 5 MΩ

3.Compressive strength: 1500V/5S

4.Fast heat diffusion, uniform heat transfer,directly heat objects on high thermal efficiency,long service life,work safe and not easy to aging.

Application for silicone rubber heater |

1. Thermal transfer equipment |

2. Prevent condensation in motors or instrument cabinets |

3. Freeze or condensation prevention in housings containing electronic equipment, for examples: traffic signal boxes, automatic teller machines, temperature control panels, gas or liquid control valve housings |

4.Composite bonding processes |

5.Airplane engine heaters and aerospace industry |

6.Drums and other vessels and viscosity control and asphalt storage |

7.Medical equipment such as blood analyzers, medical respirators, test tube heaters, etc |

8.Curing of plastic laminates |

9.Computer peripherals such as laser printers, duplicating machines |