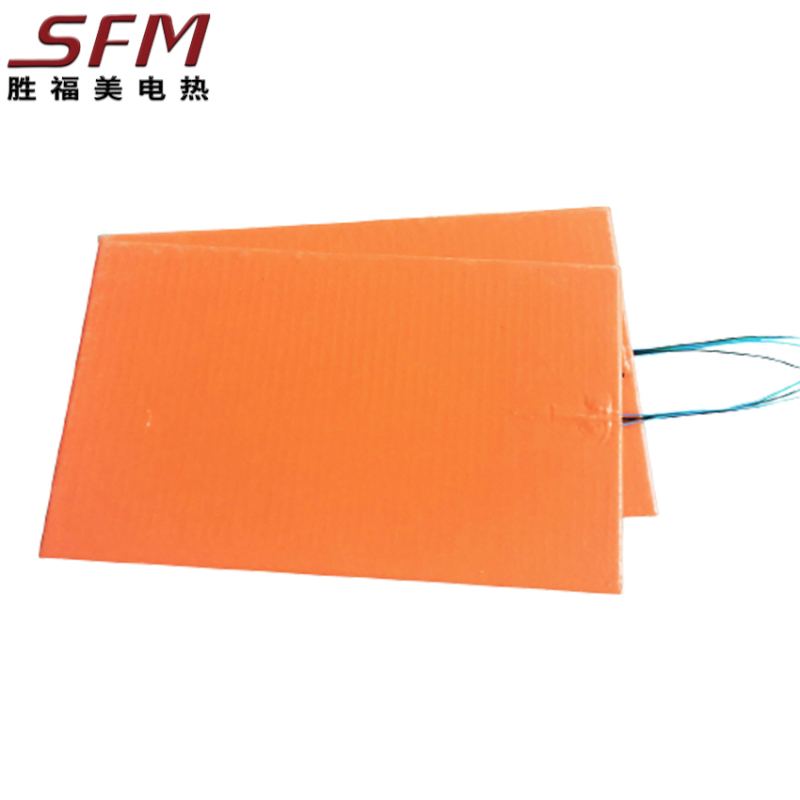

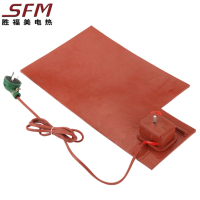

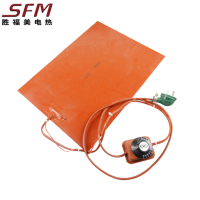

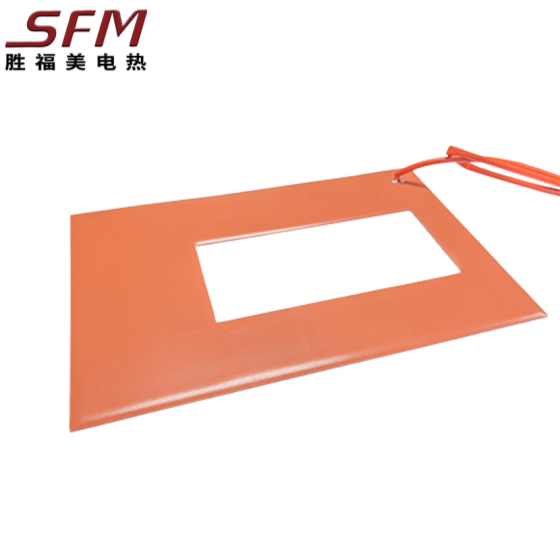

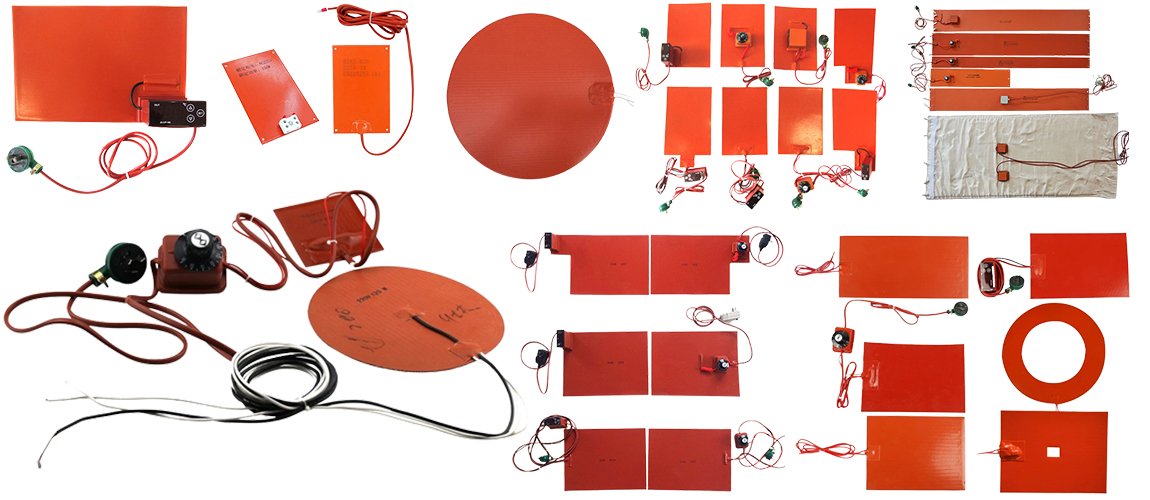

Silicone Rubber Heater With Mechanical Thermostat

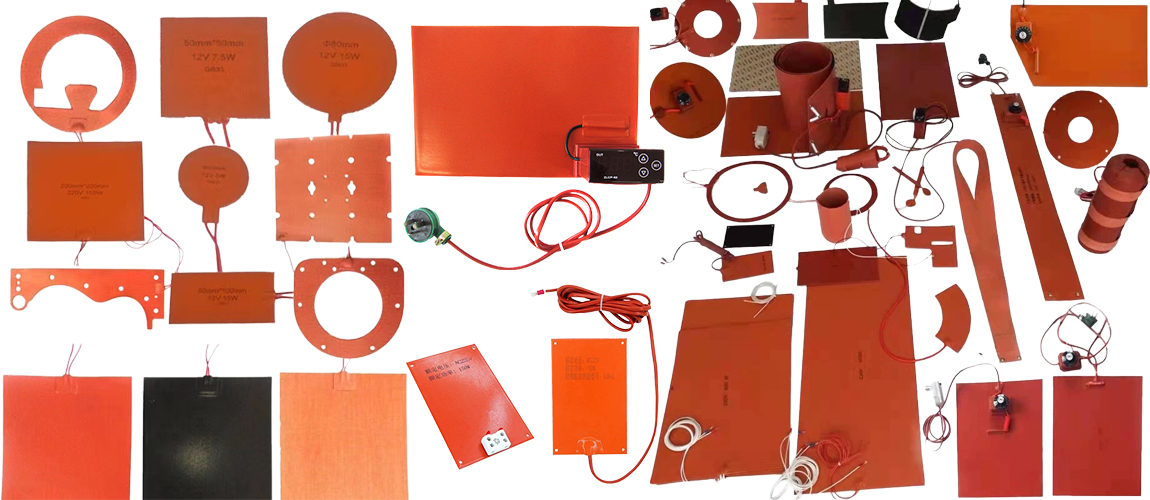

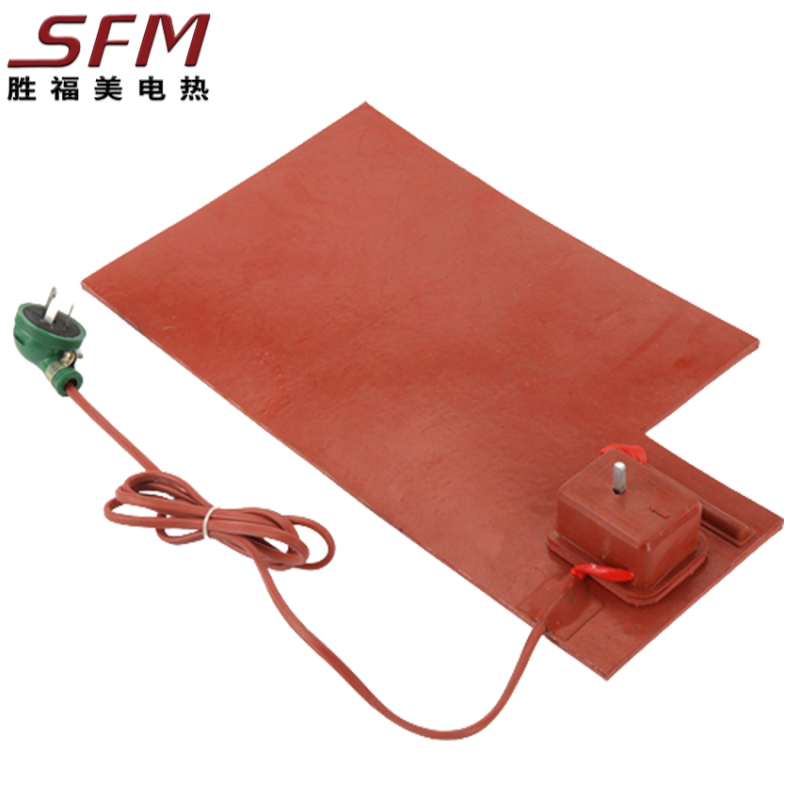

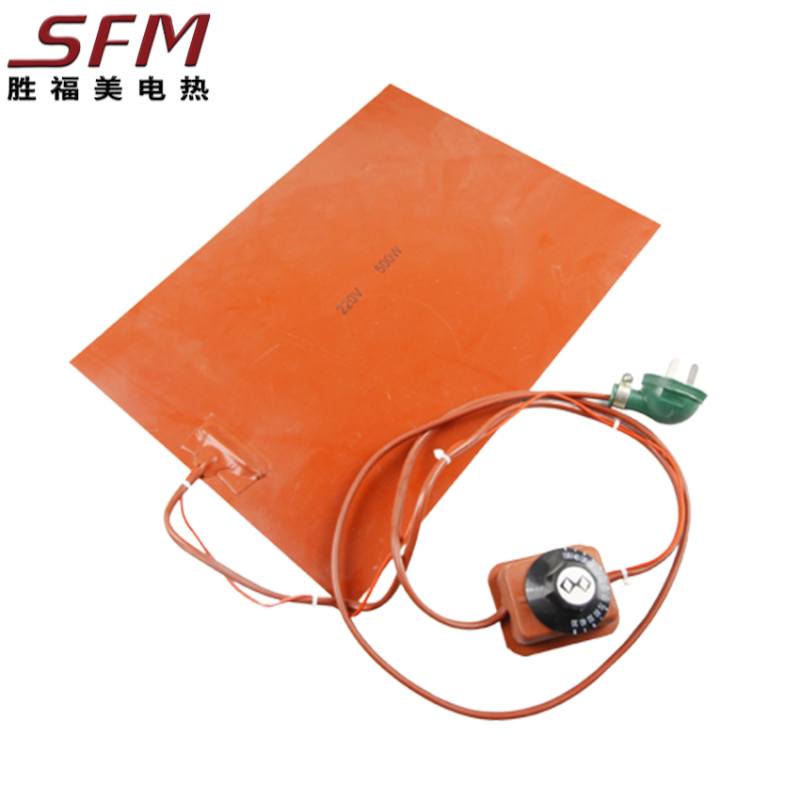

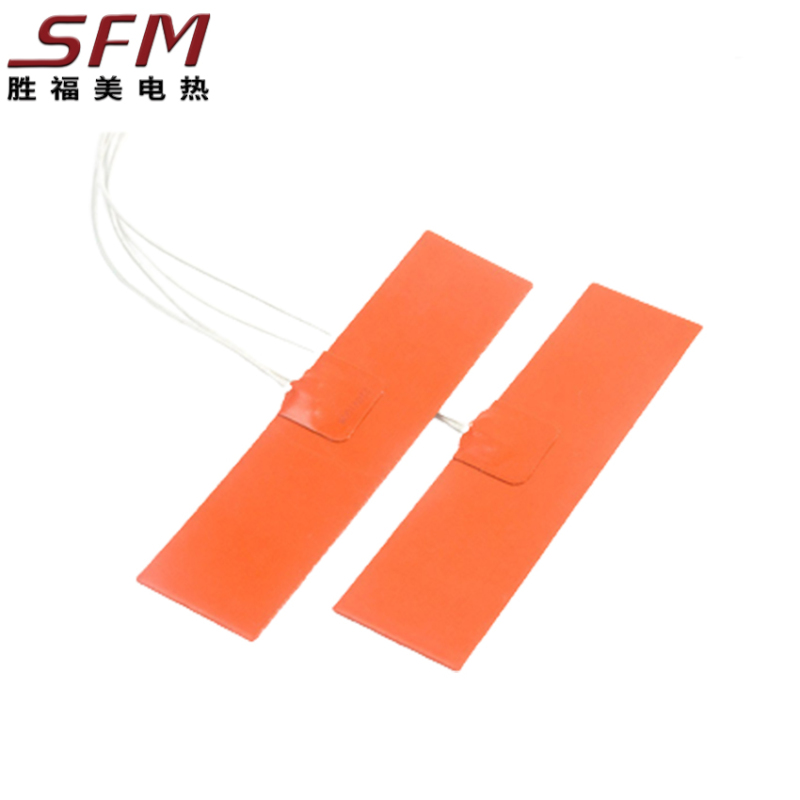

Silicone rubber heater ( silicone heating sheet, silicon rubber, silicon rubber electrothermal film heating plate etc.), silicon rubber insulating layer is made of silicone rubber and glass fiber cloth are compounded sheet( the standard thickness of 1.5mm ), it has good flexibility, can be associated with an object to be heated is close contact; the heating elements of nickel alloy foil processing form, the heating power can reach 2.1W/CM2, more uniform heating. In this way, we can let the heat transfer to any desired place.

- SFM

- china

- 2-7 day

- Information

Product Description

Name | Silicone rubber heater |

Electric resistance precision | ±10%( bigger value selected) |

Power deviation | 5% |

Mechanical pressure | 100.00kg/cm² |

Minimum bending radius | 3.20mm |

External insulation material | Silicone glass fiber |

Internal heating element | Ni-Cr alloy |

Thickness | 1~1.5mm(0.039"~0.059") |

Voltage range | 1.5-660V |

Power density range | 0.03w/cm2~2.5w/cm2 (0.19w/inch2~16.13w/inch2) |

Using temperature range | -60~250°C (-140~482°F) |

Width range | 10mm~1200mm (0.39"~47.24") |

Length range | 10mm~10000mm(0.39"~393.7") |

Product Advantage

Features for silicone rubber heater

1.Maximum temperature resistant of insulant: 300°C

2.Insulating resistance: ≥ 5 MΩ

3.Compressive strength: 1500V/5S

4.Fast heat diffusion, uniform heat transfer,directly heat objects on high thermal efficiency,long service life,work safe and not easy to aging.

Application for silicone rubber heater |

1. Thermal transfer equipment |

2. Prevent condensation in motors or instrument cabinets |

3. Freeze or condensation prevention in housings containing electronic equipment, for examples: traffic signal boxes, automatic teller machines, temperature control panels, gas or liquid control valve housings |

4.Composite bonding processes |

5.Airplane engine heaters and aerospace industry |

6.Drums and other vessels and viscosity control and asphalt storage |

7.Medical equipment such as blood analyzers, medical respirators, test tube heaters, etc |

8.Curing of plastic laminates |

9.Computer peripherals such as laser printers, duplicating machines |